What is the basic working principle of an air booster?

Nov 09, 2023

An air booster is a device used to compress air in the surroundings and provide high-pressure gas. Its basic operating precept involves a couple of steps, consisting of inhaling air, compressing air, pressurizing air and outputting high-strain gasoline. The basic operating precept of the air booster might be defined in detail below.

First, the air booster draws air from the surrounding ecosystem through a suction level. The purpose of this level is to reap the preliminary low strain air. The inhalation technique commonly takes region through one or more air inlets and filters to ensure that the air being inhaled is notably easy and free of impurities.

Next, the sucked air enters the compressor, that's one of the core components of the air booster. In a compressor, air is compressed and its volume decreases at the same time as the stress increases. The choice and layout of the compressor immediately impacts the performance of compression and the very last output pressure stage.

The compressed air then enters the booster machine. A booster gadget makes use of a sequence of booster devices, such as booster pumps or superchargers, to boost low-stress compressed air to a better stress level. This system may additionally encompass a couple of ranges of pressurization to satisfy the high-strain gasoline requirements of a particular utility.

Finally, the pressurized air is output at excessive strain. This excessive-stress gasoline may be transported through pipelines to in which it's far needed, and can also be used to supply pneumatic systems, laboratory system, and so forth. The pressure level of the output high-pressure gas is usually controlled by the system, using components such as pressure sensors, valves and regulators to ensure that the output gas is stable and meets specific needs.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

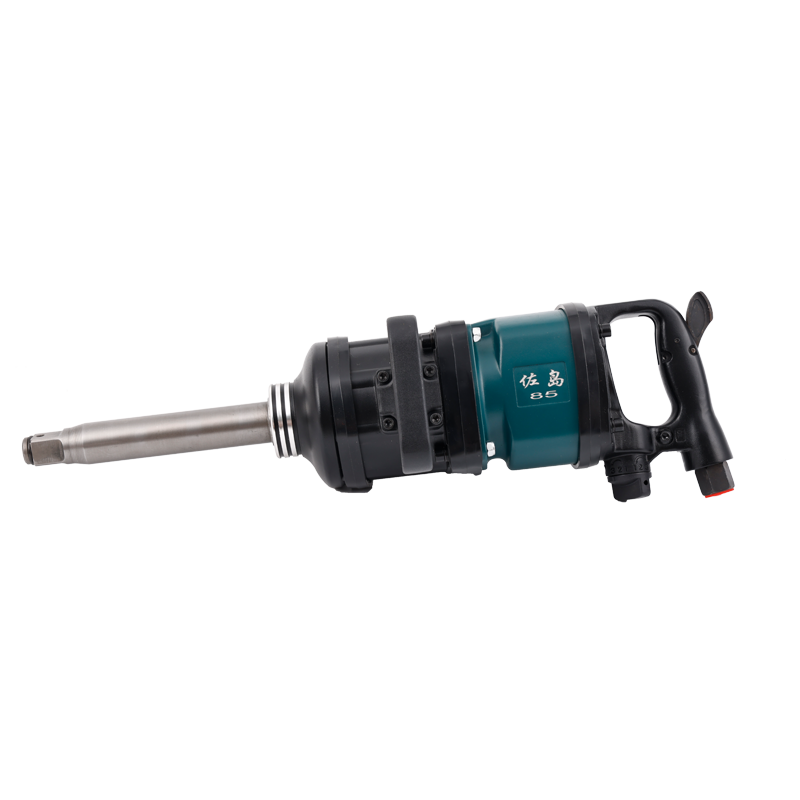

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

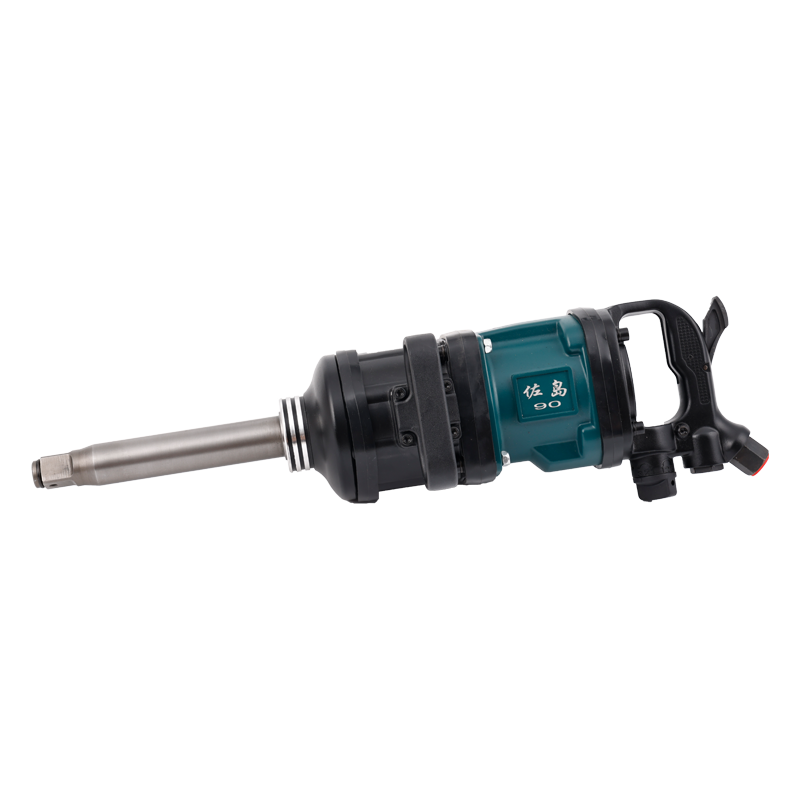

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский