How does an air sander work and what are its basic principles?

Nov 03, 2023

An air sander is a form of surface treatment device whose basic precept includes using compressed air to boost up and spray abrasives (usually sand) onto the surface of a workpiece to do away with undesirable layers, oxides, contaminants or to reap floor roughness at the surface of the fabric. Here is the simple working precept of an air sander:

Air sanders depend upon compressed air as a power source. Compressed air is generated via an air compressor and is going through a filtering and stress regulating system to ensure easy, solid compressed air.

Sand (abrasive) is loaded right into a sand tank or sand field and used to spray onto the workpiece surface. The preference of grit depends at the floor instruction venture required, along with cleansing, sprucing or getting rid of oxide layers.

The air sander mixes compressed air with sand debris thru the sandblasting nozzle and sandblasting head, and quickens it to high velocity. The layout of the sandblasting nozzle has a key impact at the spray path, blast perspective and spray drift price.

When compressed air is blended with sand debris, a high-speed sand glide is formed. This sand glide is sprayed onto the floor of the workpiece, and thru impact and friction, the floor layer, oxides or different impurities are eliminated. The sandblasting process also can trade the roughness of the workpiece surface to reap the preferred floor best.The waste and dust generated at some point of the sandblasting technique want to be disposed of. It is typically collected and filtered thru a vacuum gadget or other series system to save you environmental pollutants.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

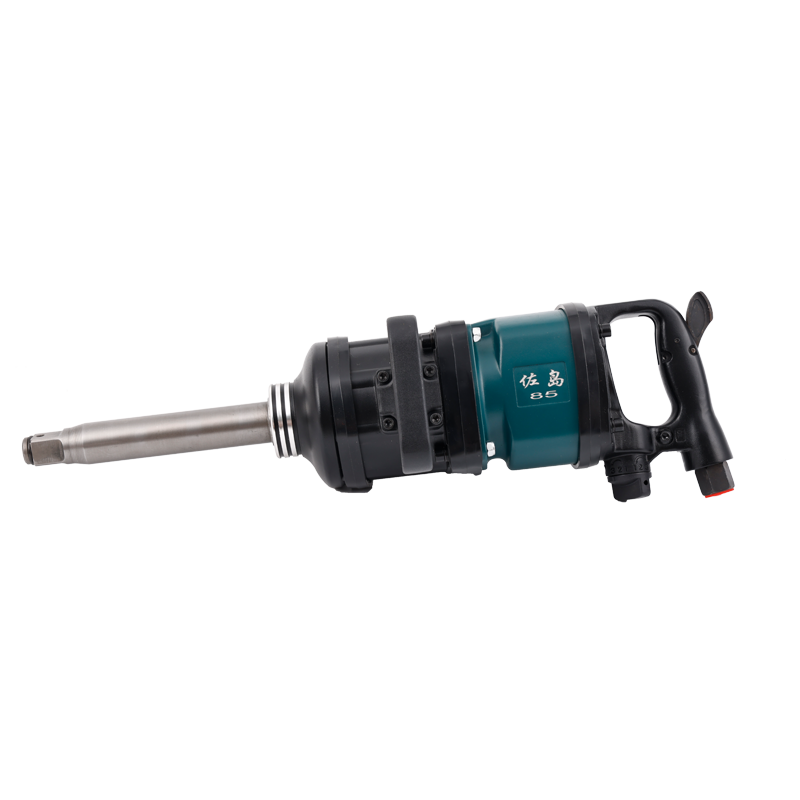

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

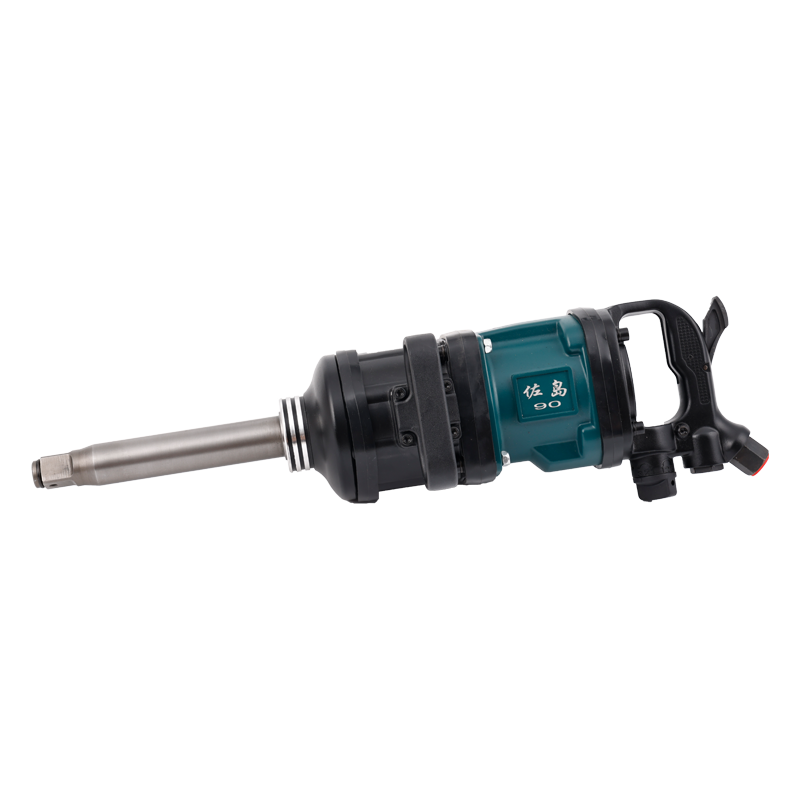

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский