How to tell if an air booster is suitable for a specific gas type

Nov 15, 2023

Determining whether or not an air booster is suitable for a specific gas type is a crucial problem because extraordinary gases may also showcase exceptional residences and behaviors all through compression and boosting. When making judgments, a sequence of things want to be taken into consideration to ensure that the air booster can keep green, secure, and solid operation while managing particular gases.

First, the chemical properties of the gas need to be considered. Different gases have distinct chemical houses, such as molecular shape, reactivity, flammability, and many others. When selecting and designing an air booster, it need to be clean whether or not the tool can safely manage the goal gas. Especially for flammable or corrosive gases, it's miles vital to ensure that the substances and production of the air booster can face up to the corrosion of the fuel and keep mechanical power.

Second, consider the compression residences of the gas. Different gases exhibit exceptional volume and pressure modifications whilst compressed. Therefore, for gases that require compression, it's far necessary to make sure that the design of the air booster can adapt to the compression houses of the target gasoline. This might also involve selecting the correct compressor type, adjusting the compression ratio, and designing the ideal raise gadget.

Temperature is some other key issue to do not forget. Different gases behave in a different way at exceptional temperatures. Some gases will produce big temperature rises while compressed, so it's miles essential to make certain that the cooling device of the air booster is effective enough to save you the gas from overheating and causing equipment failure.

Precise pressure control is another aspect of air booster suitability. When handling specific gases, very precise pressure control may be required to meet the needs of the specific application. Therefore, the control system of the air booster must be highly adjustable and able to accurately adjust and maintain the output pressure over a wide pressure range.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

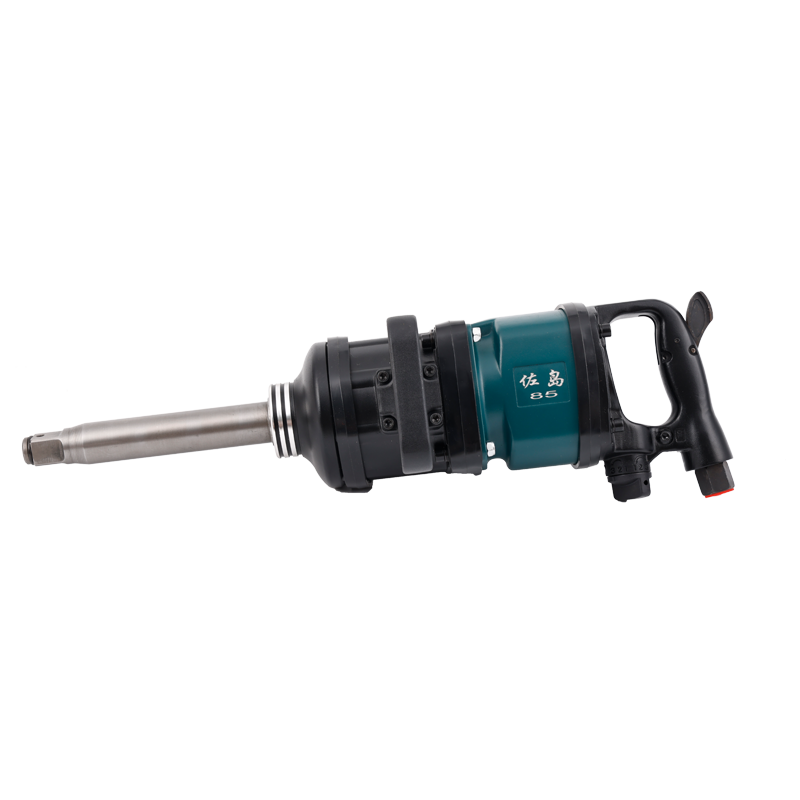

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

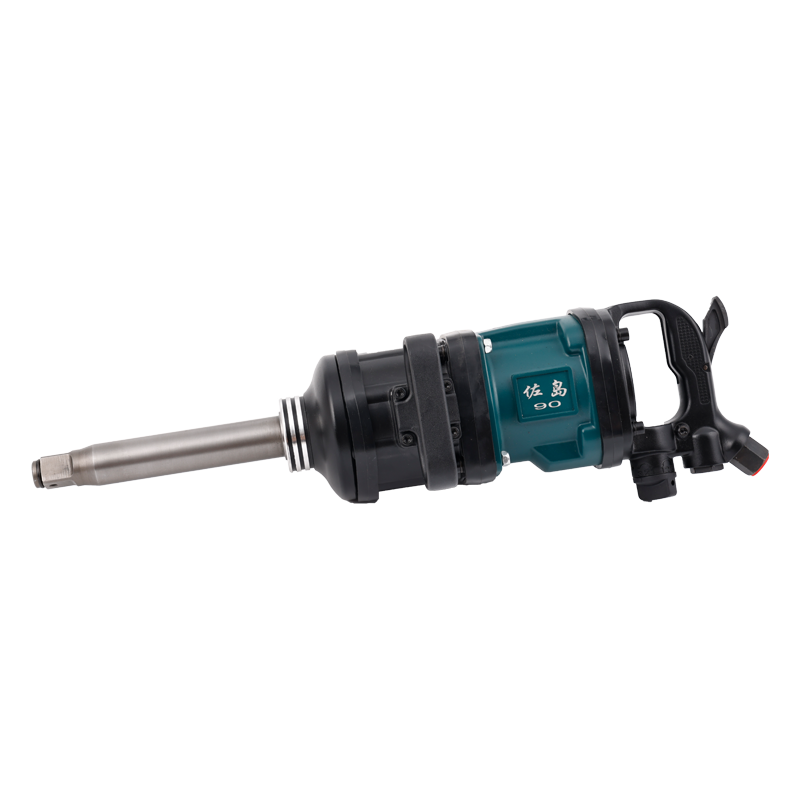

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский