Pneumatic rivet nut gun use safety instructions

May 11, 2022

The pneumatic rivet nut gun adopts innovative technology such as "automatic screwing - key pull riveting - automatic screwing" and mechanical adjustment of pull riveting stroke to achieve accurate completion of riveting nut riveting with one key. With fully automatic operation, reduce labor intensity; good versatility, low installation cost: mechanical adjustment of the riveting stroke, riveting consistency; high working tension, potassium solid and reliable; short work cycle, high installation efficiency; long life, low failure rate; less gas, economic; light weight, easy to carry; ergonomic design, comfortable operation; smooth operation, low noise: can be handheld or lifting use, suitable for It is an ideal tool for riveting the mother of riveting tickets of various materials. Widely used in automobile, railroad, container, ship, electrical switchgear, electronics, communications, ventilation, refrigeration, household appliances and other manufacturing industries.

Pneumatic rivet nut gun use safety instructions.

1. Strictly abide by the safety operating procedures, do not exceed the design scope of use.

2. The pressure of the working air source AIR RIVETER TOOL ZUODAO MACHINE NUT TOOL should not exceed 7 bar.

3. Do not disassemble the gun body, and do not remove parts that are not marked as removable in the operating instructions.

4. Hold and put away gently. Do not hit or damage the nylon gun body.

5. Do not connect other equipment or use it with other equipment without permission except when recommended.

6. Do not modify the tool by yourself, such as the screw assembly or the parts we provide, otherwise the user will be fully responsible. Please inform us if there are any modifications.

7. Do not operate tools without a complete screw assembly.

8.The air supply hose should not exceed three meters in general.

9. Before replacing the screw assembly or repairing the tool, please make sure to cut off the air supply.

10.The tool exhaust hole should be kept clear and should not be blocked or obscured.

11. Before working, the operator should choose a safe and stable position.

12.Do not start the tool towards people or equipment.

13.When not working or moving the tool, hands should be off the trigger to avoid unintentionally starting the tool.

14.Hold the tool firmly and beware of clothes, ties, long hair, rags, etc. being spun into the movable parts by the tool.

15. It is recommended that the operator wear gloves and safety glasses.

17. Do not touch the hydraulic fluid if possible. When touching the hydraulic fluid, clean it thoroughly and immediately.

18. Professional personnel are responsible for inspection, maintenance and repair of the tool, and the operator should not repair the tool.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

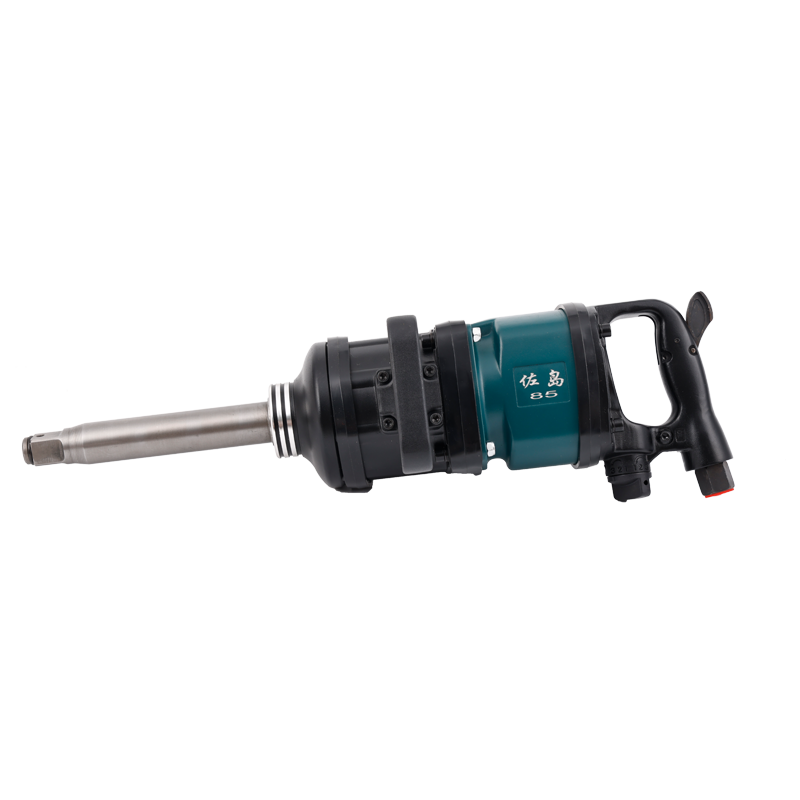

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

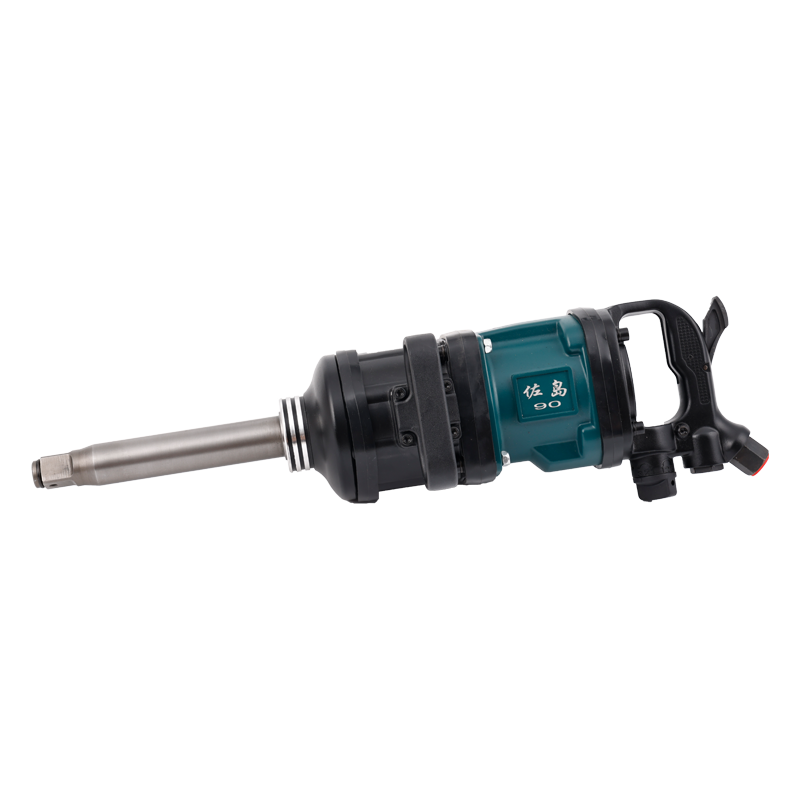

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский