Supply 6.4 mm air rivet gun, OEM air hydraulic rivet gun, air pneumatic rivet gun Factory

In the dynamic world of manufacturing and construction, the choice of tools can significantly impact efficiency, precision, and overall project success. Air rivet guns, in particular, play a pivotal role in joining materials seamlessly and securely. This article delves into the nuanced features and applications of three prominent air rivet guns – the

6.4mm Air Rivet Gun, the Air Hydraulic Rivet Gun, and the Air Pneumatic Rivet Gun.

6.4mm Air Rivet Gun:

The 6.4mm Air Rivet Gun is a precision tool designed for applications that require a specific rivet size – in this case, a 6.4mm diameter. This type of air rivet gun is characterized by its focused functionality, ideal for projects where a consistent and standardized rivet size is important. The 6.4mm diameter is commonly used in various industries, including aerospace, automotive, and metal fabrication.

One of the key advantages of the 6.4mm Air Rivet Gun is its specialized nature, catering to projects that demand uniformity in rivet dimensions. The gun typically features an ergonomic design for user comfort during prolonged use. The pneumatic operation ensures a reliable and efficient riveting process, contributing to increased productivity in assembly tasks.

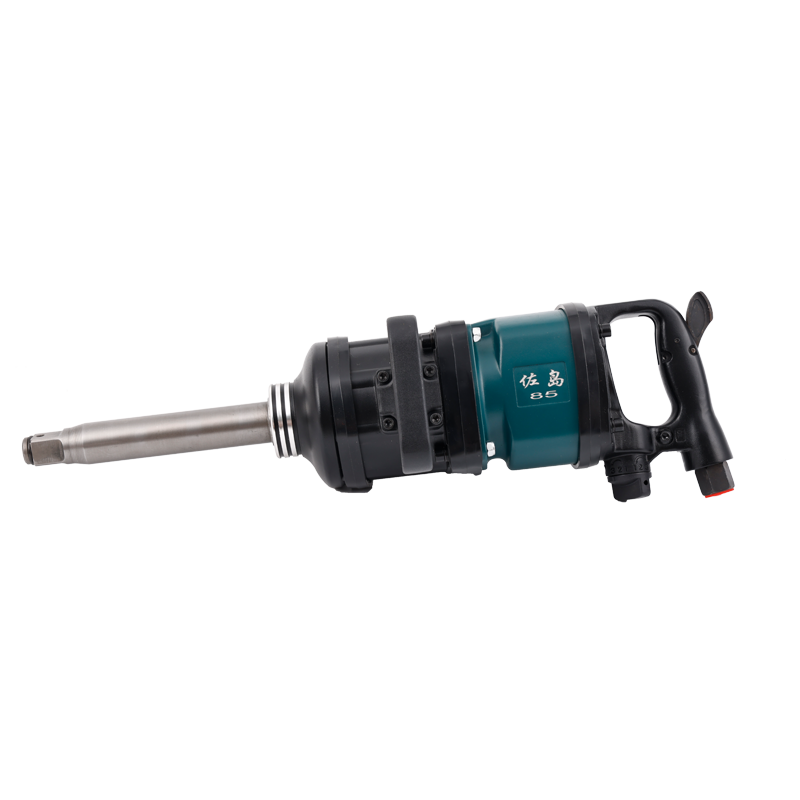

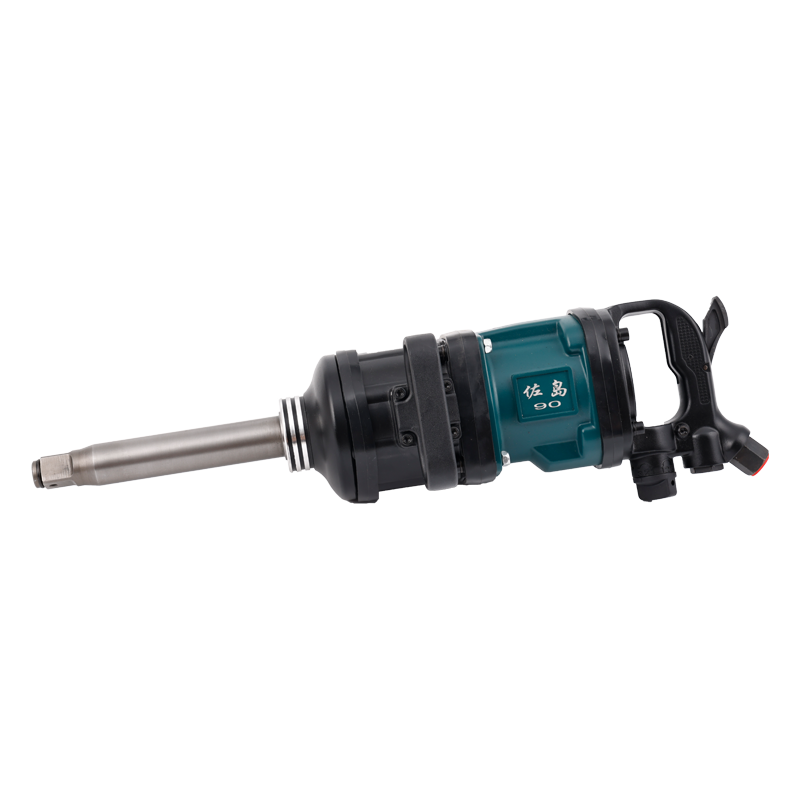

Air Hydraulic Rivet Gun:

The Air Hydraulic Rivet Gun represents a technological leap in riveting tools by combining the power of hydraulic systems with the convenience of pneumatic operation. This hybrid design offers a balance between force and precision, making it suitable for a wide range of applications, from heavy-duty industrial projects to intricate aerospace assemblies.

One of the defining features of the Air Hydraulic Rivet Gun is its ability to generate substantial force, allowing it to handle larger and more robust rivets. This makes it an ideal choice for applications where structural integrity is important, such as in shipbuilding or heavy machinery fabrication. The hydraulic system enhances control, ensuring accurate placement of rivets even in challenging materials.

Air Pneumatic Rivet Gun:

The Air Pneumatic Rivet Gun, a staple in many industries, operates solely on compressed air and is renowned for its simplicity and versatility. This type of rivet gun is widely used in assembly lines, workshops, and construction sites for its ease of use and consistent performance across various rivet sizes.

The simplicity of the Air Pneumatic Rivet Gun lies in its pneumatic mechanism, making it a reliable and cost-effective choice for a broad spectrum of applications. The lightweight design and straightforward operation contribute to user-friendly functionality, making it an excellent tool for tasks where mobility and quick riveting are important.

Comparative Analysis:

Each of these air rivet guns – the 6.4mm Air Rivet Gun, the Air Hydraulic Rivet Gun, and the Air Pneumatic Rivet Gun – has its important strengths, catering to specific requirements in different industries.

The 6.4mm Air Rivet Gun stands out for its precision in handling a specific rivet size. It excels in applications where uniformity is important, offering a streamlined solution for tasks that demand consistent 6.4mm diameter rivets. This type of air rivet gun is often preferred in industries where adherence to precise specifications is a priority.

On the other hand, the Air Hydraulic Rivet Gun distinguishes itself with its ability to generate substantial force, making it a go-to choice for heavy-duty applications. The combination of hydraulic power and pneumatic convenience allows for versatility, addressing a range of projects that require both strength and precision. Industries dealing with large-scale fabrication and structural assemblies find the Air Hydraulic Rivet Gun invaluable.

The Air Pneumatic Rivet Gun, while not as specialized as the 6.4mm model or as forceful as the hydraulic variant, serves as a reliable workhorse in numerous settings. Its simplicity and ease of use make it a preferred tool in assembly lines and construction sites, where quick and efficient riveting is important. The Air Pneumatic Rivet Gun excels in versatility, accommodating various rivet sizes and materials.

Application Specifics:

Understanding the specific applications where each air rivet gun excels is important for making an informed choice in a given industry.

The 6.4mm Air Rivet Gun finds its niche in projects that require standardized rivet dimensions. Industries such as aerospace and automotive manufacturing, where precise specifications are important, benefit from the focused functionality of this rivet gun. The 6.4mm diameter is a common requirement in these sectors, and this tool ensures accuracy in rivet placement.

The Air Hydraulic Rivet Gun shines in applications that demand both power and precision. Shipbuilding, heavy machinery fabrication, and structural assembly projects benefit from the force generated by the hydraulic system. The controlled operation of the hydraulic-pneumatic combination makes this rivet gun suitable for diverse materials and challenging working conditions.

The Air Pneumatic Rivet Gun, with its simplicity and versatility, is well-suited for tasks where speed and ease of use are important. Assembly lines, workshops, and construction sites often rely on this tool for its ability to handle various rivet sizes efficiently. Its lightweight design and straightforward operation make it a practical choice for projects that prioritize mobility and quick turnaround.

Durability and Maintenance:

Durability and maintenance considerations are important factors in evaluating the long-term reliability of any tool.

The 6.4mm Air Rivet Gun, designed for precision, often features robust construction to ensure durability. Regular maintenance, including the inspection of pneumatic components and lubrication of moving parts, contributes to its longevity. Proper care and adherence to manufacturer guidelines are important to maintain great performance.

The Air Hydraulic Rivet Gun, with its hydraulic-pneumatic system, requires periodic checks on both pneumatic and hydraulic components. Regular inspection, lubrication, and, if necessary, hydraulic fluid replacement are important for sustained performance. The durability of this tool, particularly in heavy-duty applications, justifies the attention to preventive maintenance.

The Air Pneumatic Rivet Gun, known for its simplicity, is generally easy to maintain. Regular checks on air hoses, lubrication of moving parts, and ensuring proper air pressure are standard maintenance practices. The straightforward design contributes to the tool's reliability, and routine care prolongs its operational life.

User Feedback and Ratings:

User feedback provides valuable insights into the real-world performance of air rivet guns.

The 6.4mm Air Rivet Gun often receives positive reviews for its accuracy in handling specific rivet sizes. Users in industries requiring standardized rivet dimensions appreciate the precision and reliability of this tool. The ergonomic design and ease of use also contribute to user satisfaction.

Air Hydraulic Rivet Guns, renowned for their power and versatility, garner praise for their ability to handle challenging applications. Users in heavy industries appreciate the force generated by the hydraulic-pneumatic system and the control it offers in precise rivet placement. Durability in demanding conditions is a consistent point of satisfaction.

Air Pneumatic Rivet Guns, valued for their simplicity, receive positive reviews for their reliability in various settings. Users in assembly lines and construction sites highlight the tool's ease of use, quick riveting capabilities, and versatility across different rivet sizes. The lightweight design and straightforward operation contribute to user satisfaction.

Conclusion:

In the realm of air rivet guns, the 6.4mm Air Rivet Gun, the Air Hydraulic Rivet Gun, and the Air Pneumatic Rivet Gun each carve a niche in addressing specific industry needs. The choice between these tools depends on the nature of the project, the desired riveting precision, and the force required.

The 6.4mm Air Rivet Gun excels in applications that demand uniformity and precision, making it a preferred choice in industries with strict specifications. The Air Hydraulic Rivet Gun, with its hydraulic-pneumatic power, stands out in heavy-duty applications where both force and control are important. The Air Pneumatic Rivet Gun, known for its simplicity and versatility, caters to projects prioritizing quick and efficient riveting across various sizes.