Sales air compressed hammer, Design air impact hammer, air hammer Supplier

In the realm of construction, maintenance, and manufacturing, tools that deliver power, precision, and versatility are indispensable. Among the relied-upon tools are air compressed hammers and

air impact hammers, which harness the force of compressed air to perform a wide range of tasks with efficiency and accuracy. From breaking concrete to driving fasteners and shaping metal, these tools have become important assets in various industries. In this comprehensive exploration, we delve into the evolution, capabilities, and applications of air compressed and impact hammers, highlighting their transformative impact on modern work environments.

Air compressed hammers and air impact hammers share a common foundation: both utilize compressed air as a power source to deliver high-impact force. However, they differ in their design, functionality, and intended applications.

Air compressed hammers, also known as pneumatic hammers or air chisels, are versatile tools designed for cutting, chiseling, and shaping materials such as concrete, stone, and metal. These hammers consist of a piston-driven mechanism powered by compressed air, which delivers rapid, repetitive blows to the workpiece. The force of the impact is controlled by adjusting the air pressure and the angle of the tool, allowing users to tailor the intensity of the blows to suit the task at hand.

One of the primary advantages of air compressed hammers is their versatility. With the appropriate attachment or chisel bit, these hammers can perform a wide range of tasks, from breaking up concrete and removing tile to shaping metal and carving intricate designs. Their rapid, percussive action allows for precise control and efficient material removal, making them indispensable tools in applications such as demolition, construction, and metal fabrication.

Furthermore, air compressed hammers are favored for their lightweight and ergonomic design, which reduces operator fatigue during extended use. The pneumatic power source eliminates the need for cumbersome cords or batteries, providing greater freedom of movement and maneuverability on the job site. Additionally, these hammers generate minimal vibration compared to traditional handheld tools, reducing the risk of hand-arm vibration syndrome (HAVS) and enhancing user comfort and safety.

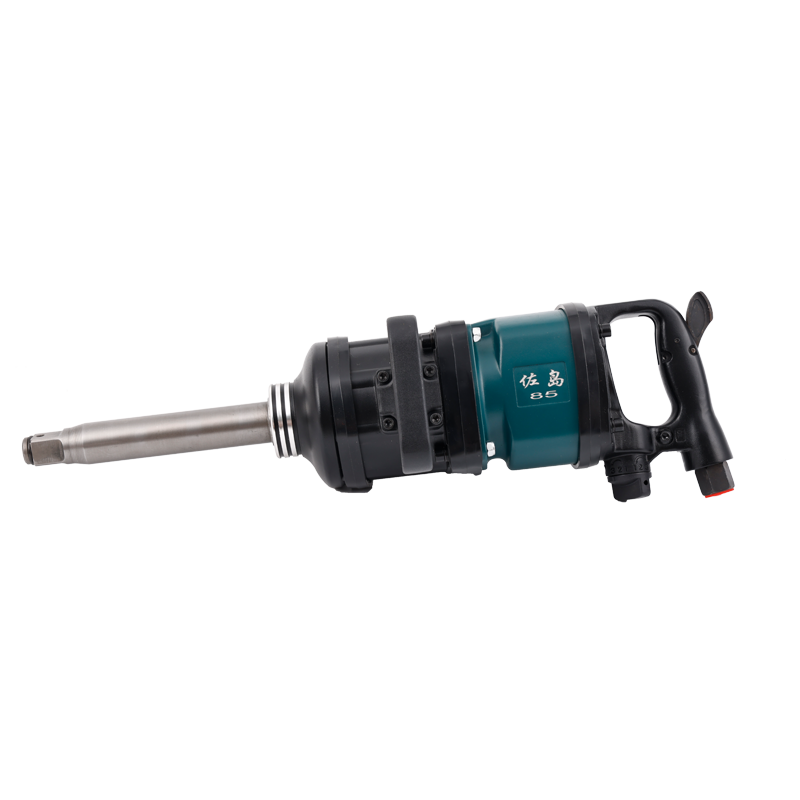

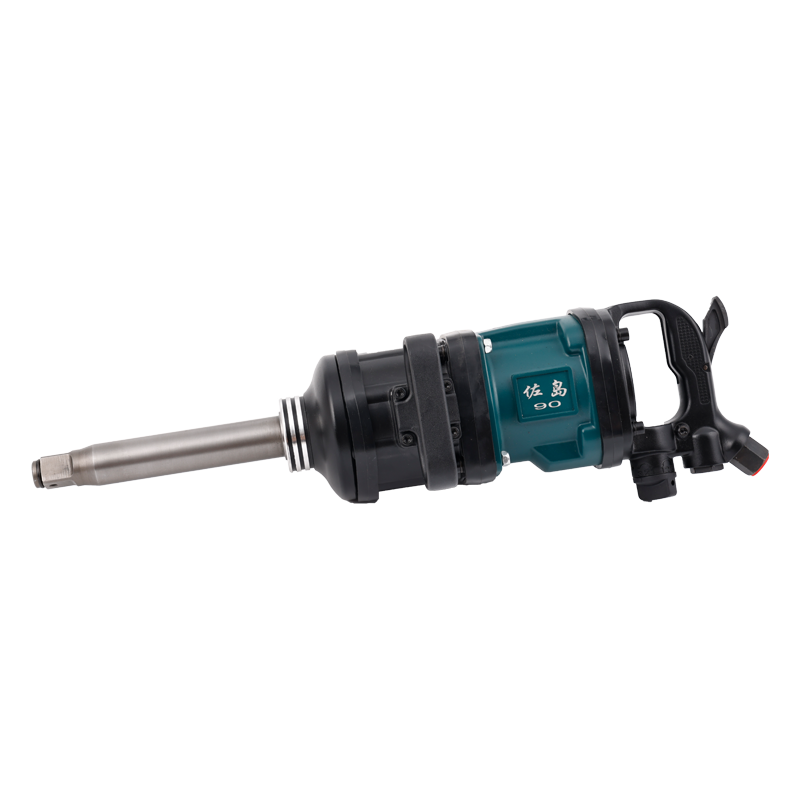

In contrast, air impact hammers, also known as pneumatic impact wrenches or air guns, are specialized tools designed for fastening and loosening bolts, nuts, and other fasteners with high torque requirements. These hammers utilize a rotary hammer mechanism powered by compressed air, which delivers rapid bursts of torque to drive or remove fasteners efficiently. The impact action allows for quick and precise fastening, even in hard-to-reach or obstructed spaces.

One of the key advantages of air impact hammers is their ability to deliver high torque output with minimal effort from the operator. The pneumatic power source provides consistent, reliable performance, allowing users to tackle even the toughest fastening tasks with ease. Whether assembling machinery, installing automotive components, or constructing steel structures, air impact hammers offer unmatched speed and efficiency, reducing assembly time and labor costs.

Moreover, air impact hammers are prized for their durability and reliability in industrial settings. Unlike electric or battery-powered tools, which may experience performance degradation over time, pneumatic tools are less prone to overheating or mechanical failure, ensuring consistent performance in demanding work environments. Additionally, air impact hammers are compatible with a wide range of sockets and accessories, allowing for versatility and adaptability across various applications and industries.

The applications of air compressed hammers and air impact hammers are diverse and far-reaching, spanning multiple industries and sectors. In construction and demolition, air compressed hammers are used for breaking up concrete, removing tile and masonry, and shaping stone or metal surfaces. Their versatility and efficiency make them indispensable tools for contractors, builders, and tradespeople working on renovation projects, infrastructure development, and structural repairs.

In manufacturing and fabrication, air compressed hammers find applications in metalworking, carpentry, and assembly operations. These hammers are used for cutting, shaping, and finishing metal components, as well as for removing welds, burrs, and excess material. Their precision and power make them valuable assets in industries such as automotive manufacturing, aerospace engineering, and shipbuilding, where tight tolerances and high-quality finishes are important.

Similarly, air impact hammers play a vital role in automotive repair and maintenance, where they are used for tire removal, suspension work, and engine repairs. Their high torque output and rapid fastening capabilities streamline assembly and disassembly tasks, reducing downtime and increasing productivity in automotive workshops and service centers.

In conclusion, air compressed hammers and air impact hammers represent the pinnacle of pneumatic tool technology, offering unmatched power, precision, and versatility in various industries and applications. Whether breaking concrete on a construction site, assembling components in a manufacturing facility, or servicing vehicles in an automotive workshop, these tools have become indispensable assets for professionals seeking efficient and reliable solutions to their toughest challenges. As technology continues to evolve, air compressed and impact hammers will undoubtedly remain important tools in the arsenal of tradespeople, craftsmen, and industrial professionals worldwide.