Analysis of the Status Quo of the Pneumatic Tool Industry

Apr 20, 2022

The use of pneumatic tools is the same as that of other power tools, even more than that. It has a small body, long life, high safety, and energy saving. As far as my country's air tool market as a whole, its varieties and specifications are relatively complete, such as air chisels, gun drills, polishing machines, impact wrenches, etc., but because its market price is much higher than that of ordinary electric tools, this is a One of the main reasons why pneumatic tools are not widely used.

my country's manufacturing industry and toggle technology started relatively late. After more than ten years, it has also developed a lot. Pneumatic tools have the characteristics of high quality, long life, high speed, high output force and high precision. Promoted and applied to various industrial sectors, and played a significant role. At present, pneumatic tools have been used in the assembly industry, machinery industry, power transportation industry, scooters, electric bicycles, motorcycle assembly, auto repair shops and AIR RIVETER TOOL ZUODAO MACHINE NUT TOOL some enterprises or manufacturers of assembly line operations.

The promising prospects of pneumatic tools are mainly reflected in three aspects: 1. Pneumatic tools have strong working ability and are more suitable for long-term work compared with ordinary power tools. 2. Pneumatic tools have strong adaptability to the environment. Pneumatic tools have strong water resistance, do not produce electric sparks, and can adapt to various bad or harsh environments; 3. Pneumatic tools have low maintenance costs. Pneumatic tools use air pressure pipeline equipment, and there is no need to replace parts like power tools.

As more and more operators move towards the brand management route, some well-known foreign products have also been introduced. In order to meet the market needs of different consumers, pneumatic tools are developing in the following directions: 1. The direction of mechatronics. In order to accurately achieve the preset target, it is necessary to use the conversion between gas and electrical signals; 2. The direction of precision. In order to make the cylinder positioning more accurate, use sensors, proportional valves, etc. to achieve precise feedback control; 3. Combined and intelligent orientation. Combinations of air cylinders, swing cylinders and vacuum suction cups have been used in material handling. The small moving objects are formed by combining the two cylinders of the guide according to the X and Y axes respectively, and also equipped with a solenoid valve and a program controller, with a compact structure and small footprint.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

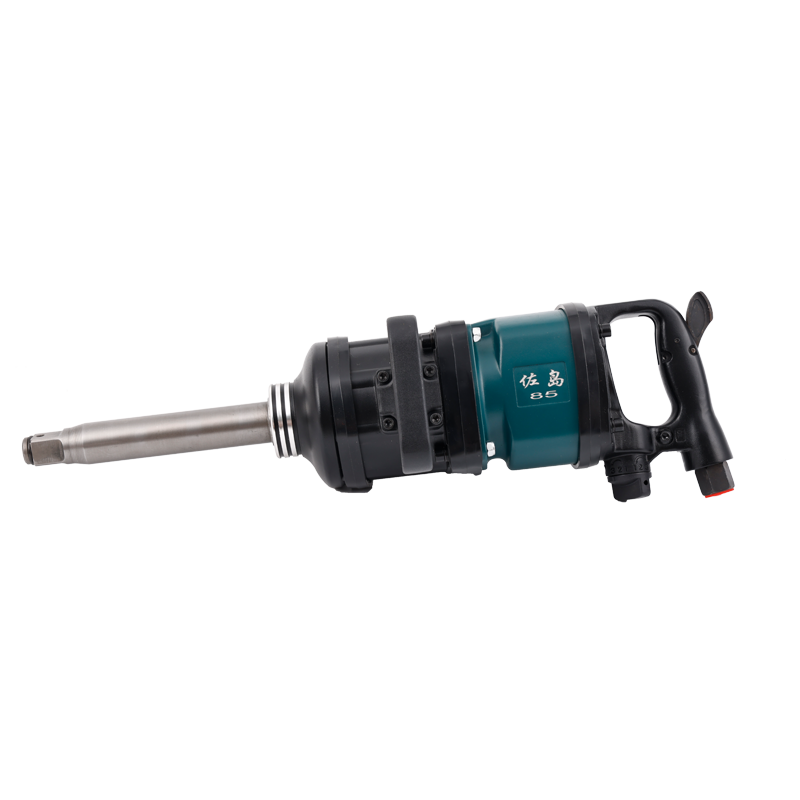

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

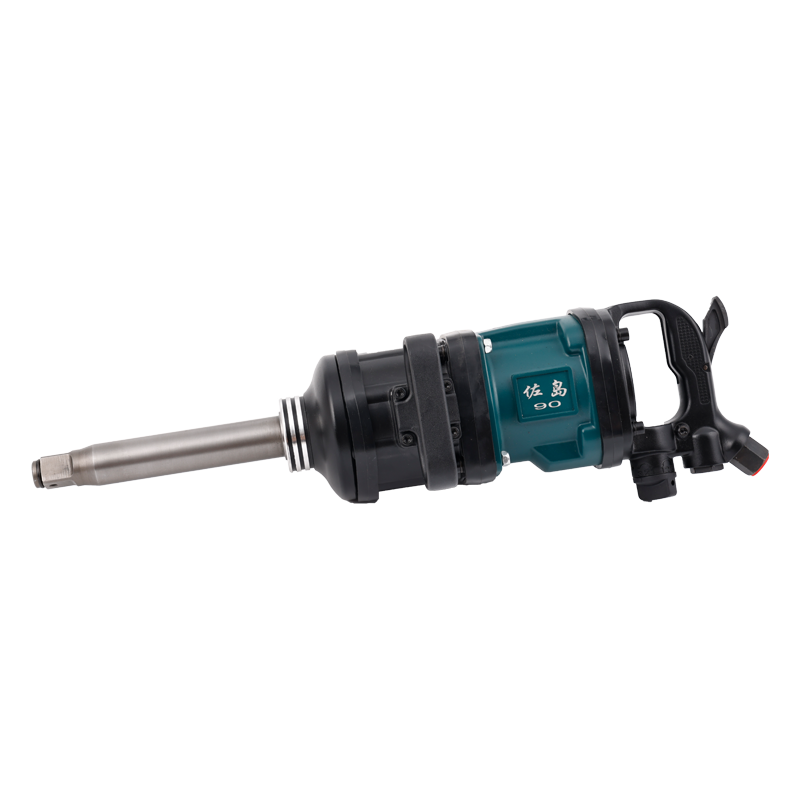

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский