Where are pneumatic impact wrenches usually used?

Feb 24, 2023

Pneumatic impact wrenches are a popular choice for a wide variety of applications. They're powerful, easy to use, and come in a range of sizes for different jobs. They're also more durable than their electric counterparts, and can be carried around for long periods of time without being easily broken or damaged.

They're not as easy to transport as cordless models, so if you want a portable tool, look for a model with big and resistant wheels. You'll also want to make sure the air compressor you're using has a high-pressure tank.

These tools typically deliver more torque than impact drivers, so they're better for loosening large bolts and nuts. This is especially true for lug nuts, which have a tendency to get stuck in tight spaces.

The hammer inside the wrench is the driving force that produces the high-torque bursts of power that impact wrenches are known for. The hammer spins rapidly when it connects to the output shaft, then releases its stored kinetic energy by striking the anvil.

Unlike a ratchet, the hammer in impact tools is always connected to the output shaft (anvil). This allows them to deliver high torques with minimal operator input.

Torque control is not as accurate as in a ratchet or air nut driver. But engineers are working to develop electronic torque transducers that will enable more precise measurements of the amount of torque applied.

The hammer inside an impact wrench can produce 90-100 dB of noise pollution, which is why I recommend wearing hearing protection equipment whenever you use one for longer than a few minutes. Similarly, vibration produced by the impact wrench is also harmful to your health, so I would always advise against using it on hard surfaces such as concrete or asphalt.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

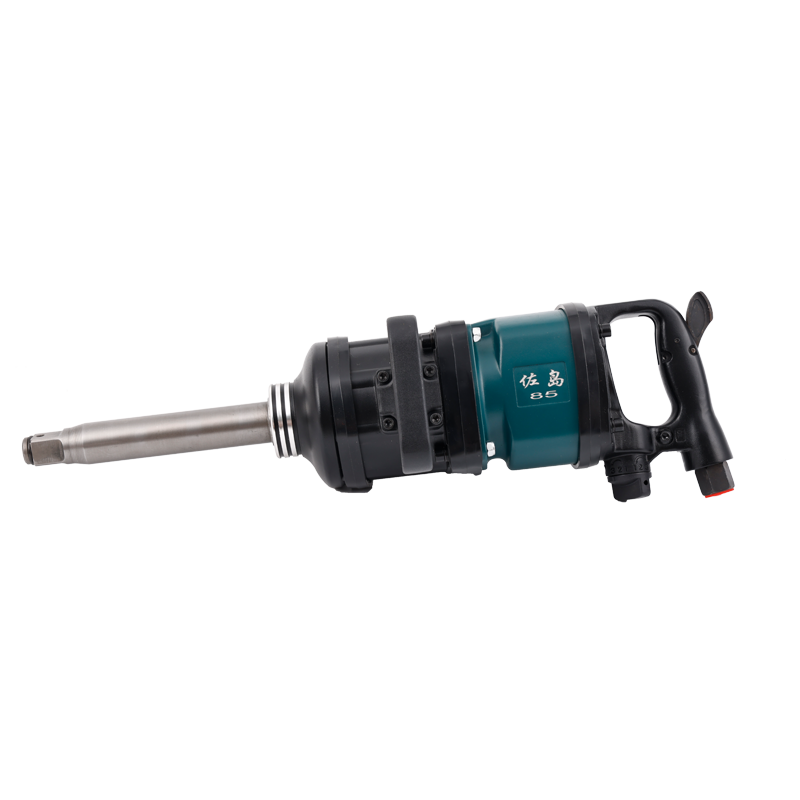

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

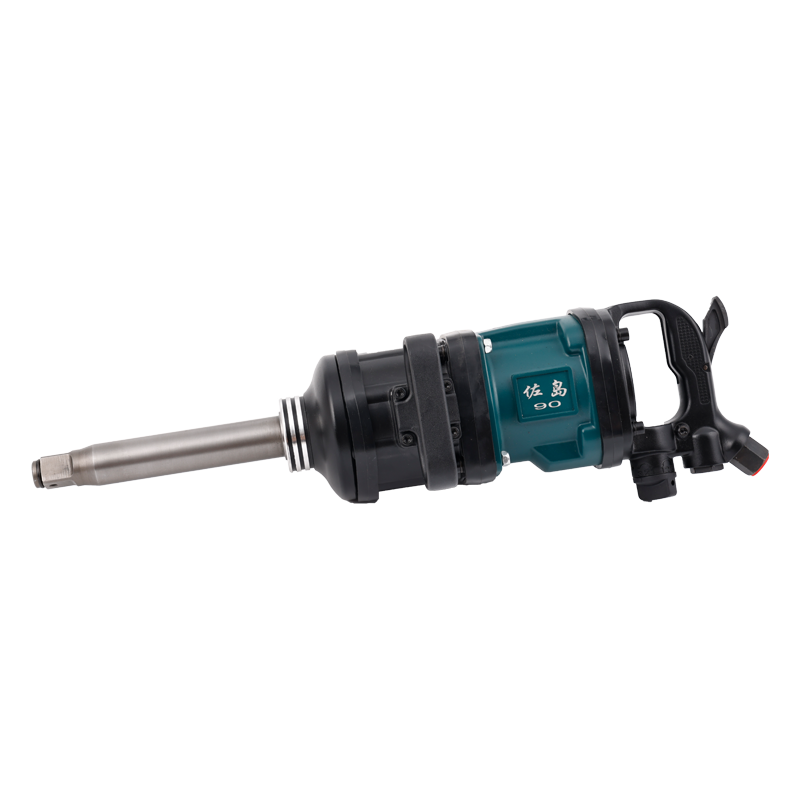

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский