What pneumatic impact wrench Are Used For?

Jun 01, 2023

Pneumatic impact wrenches, also known as air impact wrenches or air guns, are powerful tools commonly used in various industries and applications. Here are some of the main uses for pneumatic impact wrenches:

Automotive and Mechanical Work: Pneumatic impact wrenches are extensively used in automotive repair and mechanical work. They are ideal for loosening and tightening lug nuts on vehicle wheels, making tire changes faster and more efficient. Impact wrenches are also employed in assembly lines, engine repairs, suspension work, and other mechanical applications where high torque is required.

Construction and Carpentry: In the construction industry, pneumatic impact wrenches are utilized for heavy-duty fastening tasks. They are valuable for driving screws, bolts, and other fasteners into various materials, including wood, metal, and concrete. They are commonly used in framing, decking, roofing, and other construction applications.

Manufacturing and Industrial Settings: Pneumatic impact wrenches find widespread use in manufacturing and industrial settings. They are employed for assembly and disassembly of machinery, equipment, and components. Impact wrenches provide high torque output, making them suitable for tasks that involve large bolts, nuts, and threaded connections.

Maintenance and Repair: Pneumatic impact wrenches are valuable tools in maintenance and repair work across different industries. They are used for tasks such as equipment maintenance, industrial machinery repair, facility maintenance, and infrastructure repairs. Impact wrenches allow for efficient and quick tightening or loosening of fasteners, saving time and effort.

HVAC and Plumbing: In HVAC (Heating, Ventilation, and Air Conditioning) and plumbing systems, pneumatic impact wrenches come in handy for installing or removing large threaded connections, such as pipe fittings, flanges, and couplings. They assist in tightening or loosening these connections effectively, ensuring proper sealing and assembly.

Heavy Equipment and Agriculture: Pneumatic impact wrenches are employed in heavy equipment and agriculture industries for maintenance, repair, and assembly tasks. They are used for tasks like removing and installing bolts on construction machinery, agricultural equipment, and other heavy-duty applications.

Industrial Assembly Lines: Pneumatic impact wrenches are widely used on assembly lines, especially in industries that involve mass production. They provide fast and efficient tightening of fasteners, allowing for high productivity and consistency in assembly processes.

Pneumatic impact wrenches offer high torque output and are known for their power, speed, and reliability. They are favored for their ability to deliver strong rotational force without excessive user effort. However, it's important to select the appropriate impact wrench for specific applications, considering factors such as torque requirements, size of fasteners, and workspace limitations.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

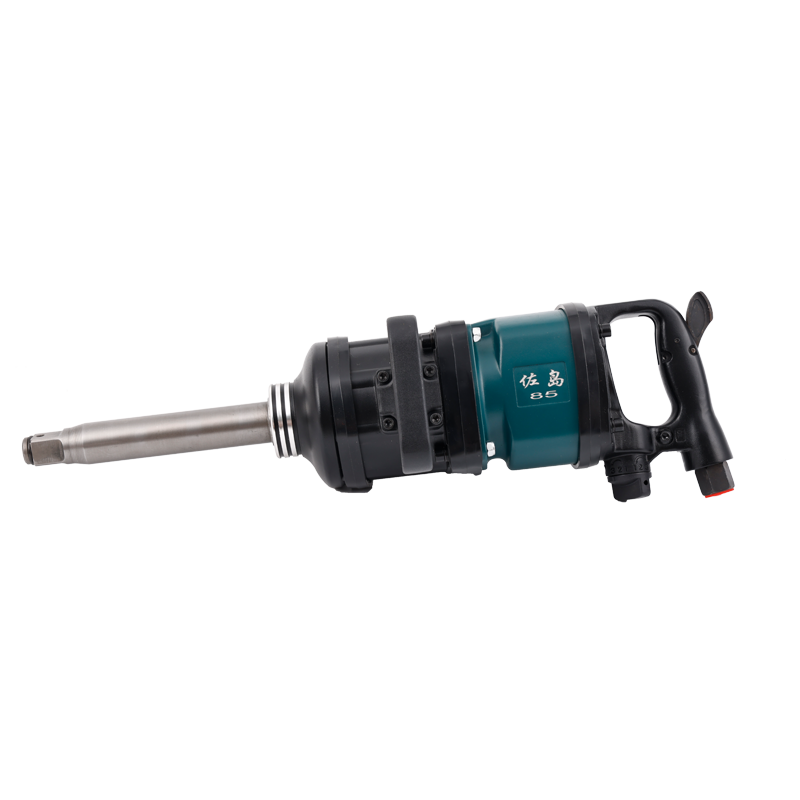

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

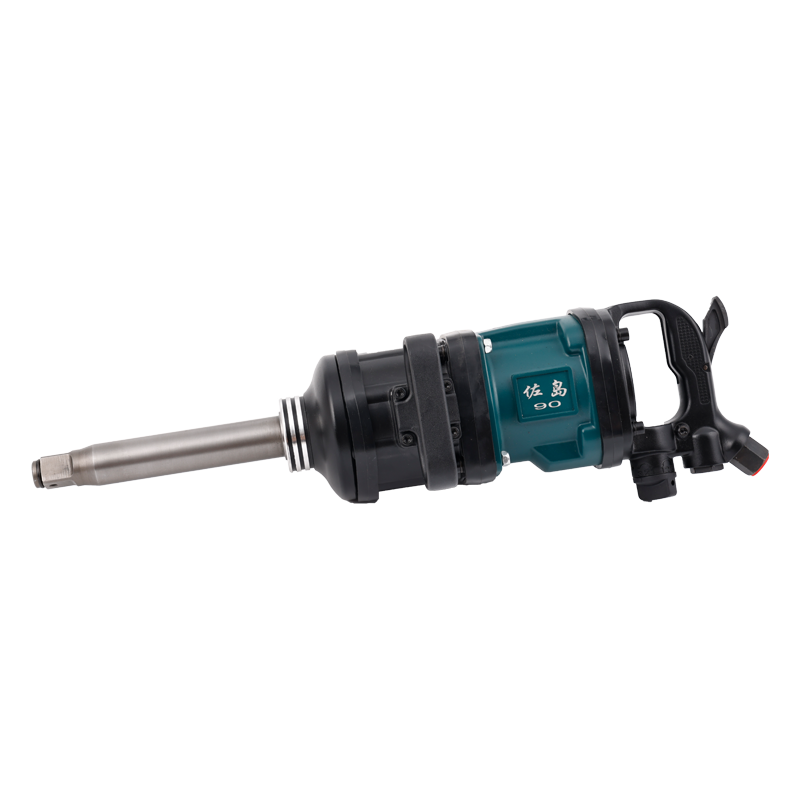

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский