What Is An Air Booster?How to Use?

Apr 07, 2023

An AIR BOOSTER takes pre-compressed air from your existing plant system or a low pressure compressor and increases it to the desired higher pressure. They are ideal for applications where plant air pressure is not adequate to meet the needs of specific equipment.

Booster Systems: Saves Money, Improves Performance and Reduces Maintenance requirements

When there is a lack of available air pressure in a plant, boosting is the most economical option to keep equipment running at full capacity. It is also a great way to ensure that all of your compressed air systems are working properly.

AIR & GAS BOOSTERS: Increase air and gas pressure to meet the demands of equipment and to maintain the proper balance between supply and demand without costly and complex high-pressure systems or relocating your air lines. They also help reduce downtime and production loss by providing a reliable source of air to critical points and processes.

The basic air booster unit is an oversized, self-contained, air amplification device that uses reciprocating pistons to increase the input pressure of pneumatic actuators, thus amplification of their output force. The boosted output pressure is typically double that of the inlet pressure.

This type of air amplification is especially useful in industrial environments where space constraints make it impossible or impractical to use electrically powered devices. The booster has integral valve components that reciprocate the air pistons to achieve this amplification. The unit can be supplied with or without a pressure regulator.

Booster Regulators: Can be used as an add-on to an existing air line or on a branch line. They can double the existing main line pressure to match the required air flow and can be controlled with a simple, compact control panel.

A booster is a simple, easy to install and maintenance free way to raise the pressure of your compressed air. They provide a safe and effective solution for localized air pressure intensification with a variety of signal to output pressure ratios to choose from.

How to Use?

An air booster is a safe, effective and reliable way to provide a steady supply of air for critical applications. It is a safe alternative to increasing the pressure of a compressor and can be used with a wide range of compressed air and gas-dependent applications.

It is a simple and effective way to provide a steady supply of air to critical applications, such as welding, cutting, blasting, grinding and other manufacturing processes. They are an efficient and affordable solution for overcoming low plant air pressure and maintaining air supply pressures up to and above the manufacturer’s specifications.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

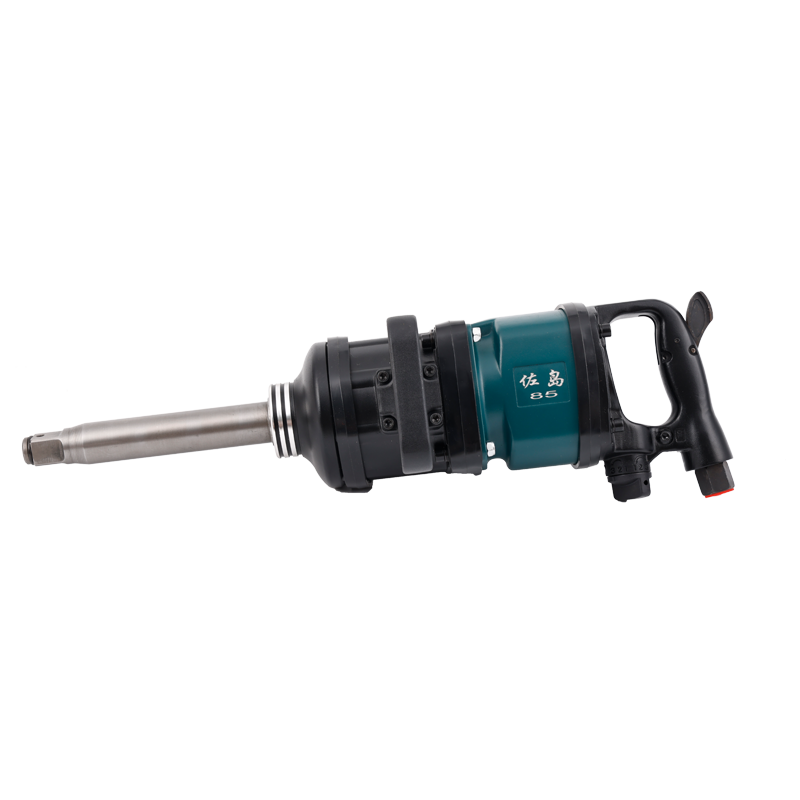

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

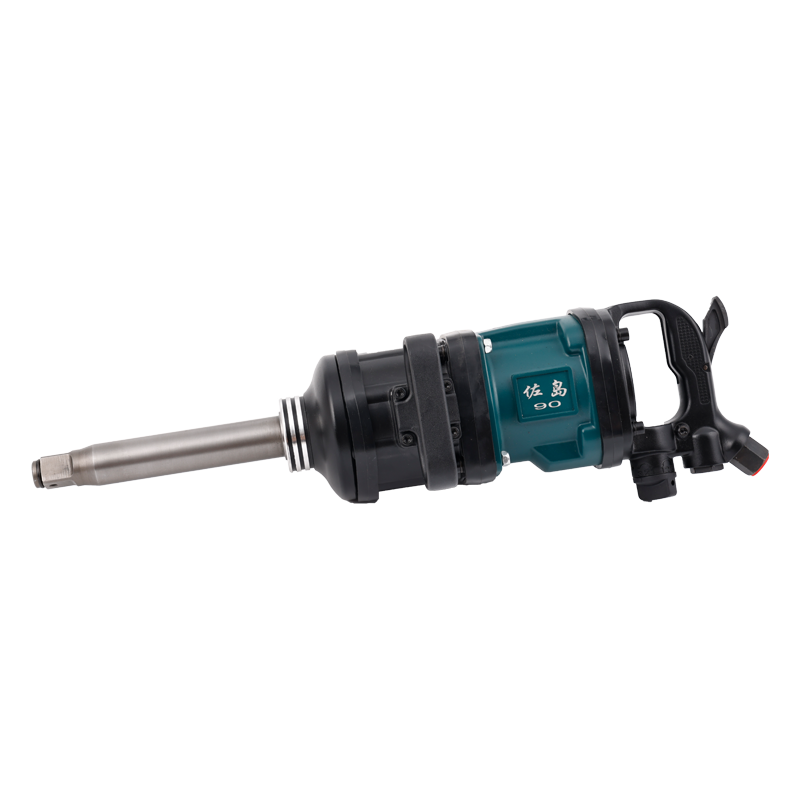

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский