What are components of an air hammer?

Jun 15, 2023

An air hammer, also known as an air chisel or pneumatic hammer, is a handheld power tool that uses compressed air to deliver high-impact blows. It is commonly used in construction, metalworking, automotive repair, and other applications that require cutting, shaping, or breaking metal or other materials.

The primary components of an air hammer include:

Handle: The handle provides a grip for the operator to hold and control the tool. It is typically made of a non-slip material for comfort and safety during use.

Trigger: The trigger is located on the handle and allows the operator to control the activation of the air hammer. Squeezing the trigger releases compressed air and initiates the hammering action.

Barrel: The barrel houses the internal mechanism of the air hammer, including the piston and impact mechanism. It directs the air pressure and controls the movement of the piston.

ZD250 2100BPM OVERALL LENGTH 235MM LONG STROKE ZUODAO AIR HAMMER

product advantages:

Item Sku.: ZD250

Type: Air Hammer

Working Pressure: 0.6-0.8Mpa

Chisel shank: 10.2mm

Stroke: 76mm

Piston: The piston is a cylindrical component inside the barrel that moves back and forth when the trigger is activated. The movement of the piston generates the striking action of the air hammer.

Impact Mechanism: The impact mechanism converts the linear motion of the piston into a high-impact hammering action. It typically consists of a chisel or a pointed tip that strikes against a surface, causing material to be cut, shaped, or broken.

Air Inlet: The air inlet is located on the handle or the bottom of the air hammer and is used to connect the tool to a compressed air source, such as an air compressor, through an air hose.

The primary components of an air hammer include:

Handle: The handle provides a grip for the operator to hold and control the tool. It is typically made of a non-slip material for comfort and safety during use.

Trigger: The trigger is located on the handle and allows the operator to control the activation of the air hammer. Squeezing the trigger releases compressed air and initiates the hammering action.

Barrel: The barrel houses the internal mechanism of the air hammer, including the piston and impact mechanism. It directs the air pressure and controls the movement of the piston.

ZD250 2100BPM OVERALL LENGTH 235MM LONG STROKE ZUODAO AIR HAMMER

product advantages:

Item Sku.: ZD250

Type: Air Hammer

Working Pressure: 0.6-0.8Mpa

Chisel shank: 10.2mm

Stroke: 76mm

Piston: The piston is a cylindrical component inside the barrel that moves back and forth when the trigger is activated. The movement of the piston generates the striking action of the air hammer.

Impact Mechanism: The impact mechanism converts the linear motion of the piston into a high-impact hammering action. It typically consists of a chisel or a pointed tip that strikes against a surface, causing material to be cut, shaped, or broken.

Air Inlet: The air inlet is located on the handle or the bottom of the air hammer and is used to connect the tool to a compressed air source, such as an air compressor, through an air hose.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

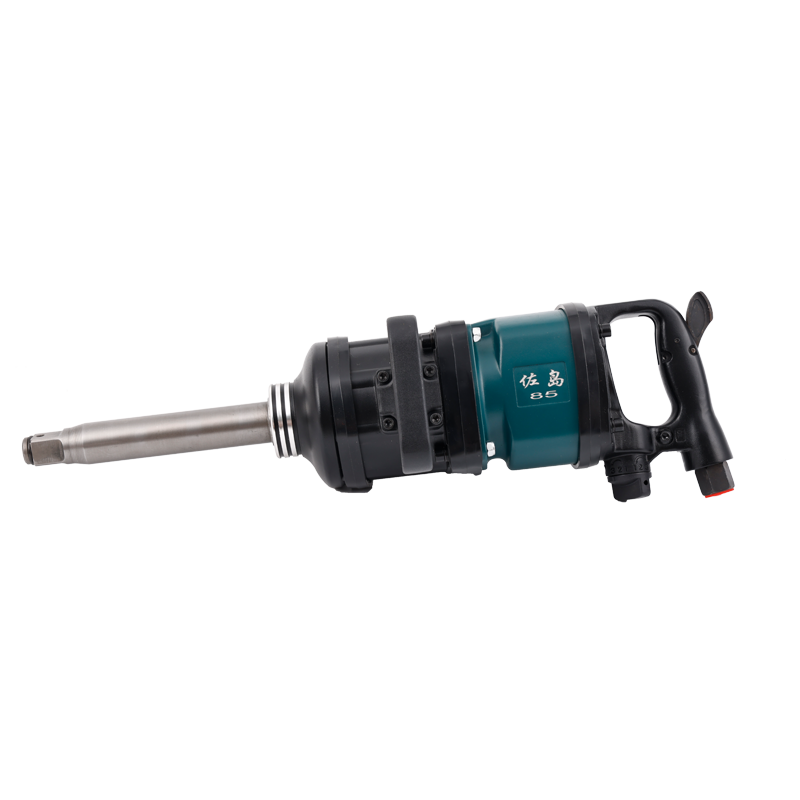

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

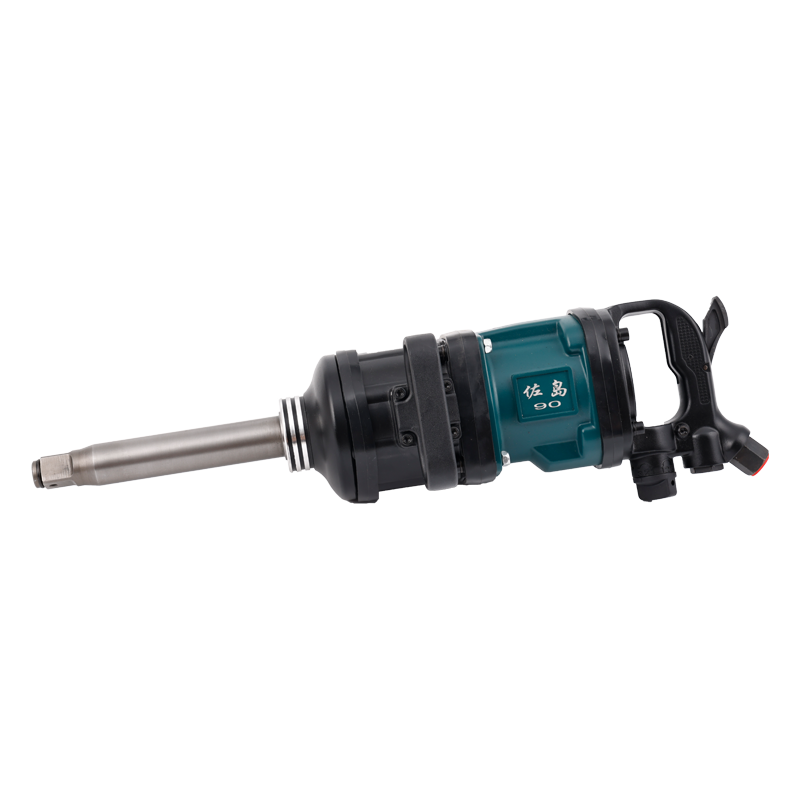

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский