Sales mini air ratchet wrench, Design pneumatic air ratchet wrench, air impact ratchet wrench Supplier

In the realm of mechanical work, the efficiency and precision of tools play a pivotal role in achieving greatresults. Among the arsenal of tools, the Mini Air Ratchet Wrench, Pneumatic Air Ratchet Wrench, and

Air Impact Ratchet Wrench stand out as importantinstruments for professionals and hobbyists alike. This article delves into the important features, applications, and advantages of these air ratchet wrenches, shedding light on their pivotal role in various mechanical tasks.

Mini Air Ratchet Wrench: Compact Powerhouse for Precision

1. Compact Design and Portability:

The Mini Air Ratchet Wrench is characterized by its compact and lightweight design. This portable powerhouse offers the advantage of maneuverability in tight spaces, making it an ideal choice for tasks where conventional wrenches may struggle to reach.

2. Precision in Tight Spaces:

The primary advantage of the mini variant lies in its ability to navigate and operate in confined spaces. With a smaller head and reduced size, it excels in tasks where precision is important, such as working on engines, machinery, or intricate assemblies.

3. Variable Speed Control:

Many Mini Air Ratchet Wrench models feature variable speed control, allowing users to adjust the tool's speed based on the specific requirements of the task at hand. This precision control enhances the versatility of the wrench across a range of applications.

4. Versatility in Applications:

Despite its compact size, the Mini Air Ratchet Wrench is versatile and can handle various tasks, including fastening and loosening nuts and bolts in automotive repairs, machinery maintenance, and other applications where space is a limiting factor.

5. Ideal for Automotive Work:

Mechanics often find the Mini Air Ratchet Wrench importantin automotive work. The tool's compact design allows for easy access to tight spaces within the engine compartment, making it an important companion for professionals working on vehicle repairs and maintenance.

Pneumatic Air Ratchet Wrench: Harnessing Air Power for Efficiency

1. Powerful Pneumatic Operation:

The Pneumatic Air Ratchet Wrench operates on compressed air, harnessing the power of pneumatics for efficient and forceful performance. This design ensures a consistent power output, making it a reliable choice for a wide array of mechanical tasks.

2. Speed and Torque:

Pneumatic Air Ratchet Wrenches are renowned for their high speed and torque capabilities. The pneumatic power source enables these tools to deliver rapid rotations and substantial torque, allowing for quick and effective fastening and loosening of nuts and bolts.

3. Reduced Operator Fatigue:

The pneumatic operation minimizes operator fatigue, as the tool's power is derived from compressed air rather than manual effort. This is particularly advantageous in tasks that require prolonged use, where reduced fatigue contributes to increased efficiency.

4. Durable and Low Maintenance:

Pneumatic tools, including air ratchet wrenches, are known for their durability and low maintenance requirements. The absence of complex internal components contributes to their robustness, making them suitable for demanding work environments.

5. Wide Range of Applications:

From automotive repairs to construction projects, Pneumatic Air Ratchet Wrenches find applications across diverse industries. The combination of power, speed, and reliability makes them versatile tools for professionals seeking efficiency and precision.

Air Impact Ratchet Wrench: Merging Power and Precision

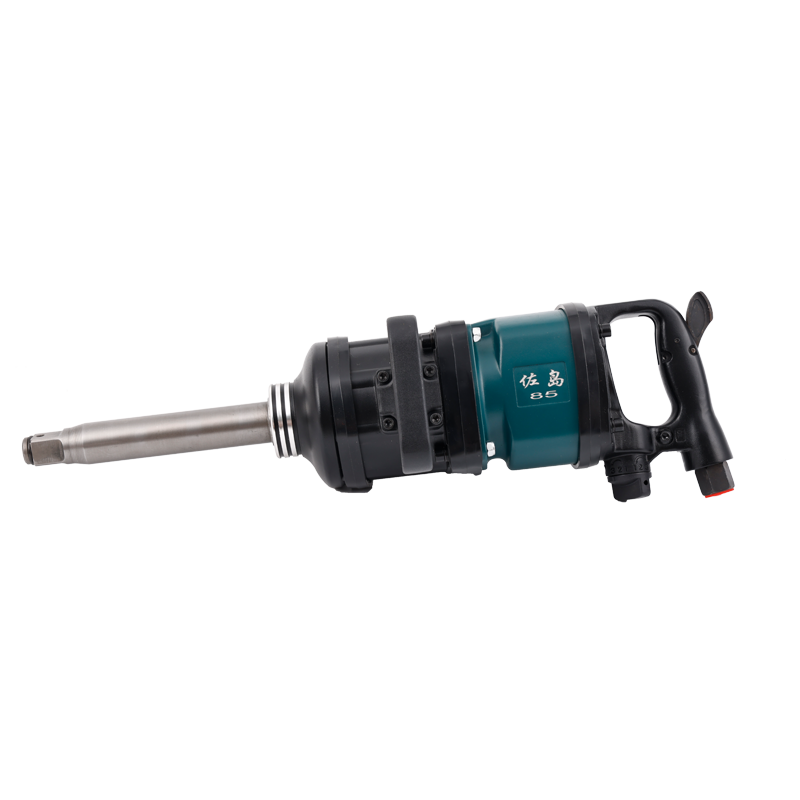

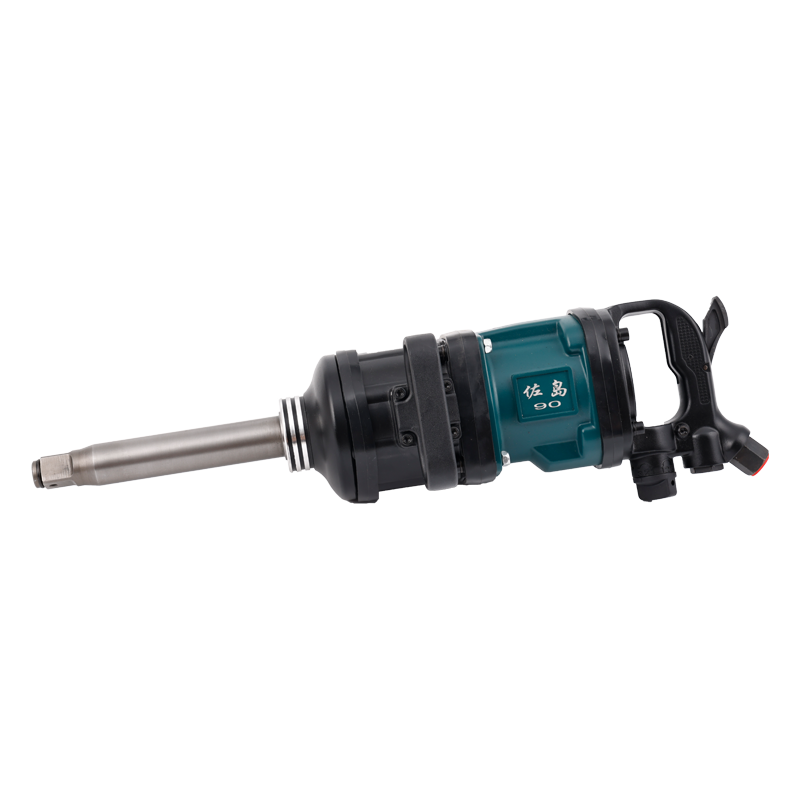

1. Impact Mechanism for Added Power:

The standout feature of the Air Impact Ratchet Wrench is its impact mechanism. This mechanism delivers powerful rotational forces, enhancing the tool's capability to handle tough fastening and loosening tasks. It's particularly effective in scenarios where high torque is required.

2. High Torque Output:

Air Impact Ratchet Wrenches are designed to provide high torque output, making them suitable for heavy-duty applications. This feature is especially valuable in industrial settings, such as manufacturing and construction, where robust tools are important.

3. Quick and Efficient Operation:

The impact mechanism enables these wrenches to deliver quick and efficient results. Whether it's removing stubborn bolts or rapidly fastening nuts, the Air Impact Ratchet Wrench excels in tasks that demand speed and power.

4. Versatility Across Industries:

These wrenches find widespread use in various industries, including automotive, construction, and manufacturing. Their ability to handle a broad range of applications, coupled with the impact mechanism, positions them as importanttools in the professional toolkit.

5. Reduced Manual Effort:

The impact mechanism reduces the need for manual effort, as the tool's power is harnessed from the air supply. This not only enhances efficiency but also minimizes operator strain during prolonged use.

Applications Across Industries:

1. Automotive Maintenance and Repair:

All three types of air ratchet wrenches find extensive use in automotive maintenance and repair. The Mini Air Ratchet Wrench is favored for its maneuverability in tight engine spaces, the Pneumatic Air Ratchet Wrench for its power and efficiency, and the Air Impact Ratchet Wrench for its ability to handle heavy-duty tasks.

2. Construction and Manufacturing:

In construction and manufacturing, the versatility of air ratchet wrenches shines. From assembling components to tightening bolts in structural elements, these tools play a important role in ensuring precision and efficiency in a wide array of tasks.

3. Machinery Maintenance:

Professionals engaged in machinery maintenance benefit from the compact design of the Mini Air Ratchet Wrench for intricate tasks, the power of the Pneumatic Air Ratchet Wrench for general maintenance, and the impact mechanism of the Air Impact Ratchet Wrench for tackling stubborn fasteners.

4. Industrial Assembly Lines:

Air ratchet wrenches are important to industrial assembly lines where efficiency and speed are important. The ability to choose the appropriate type based on the specific task at hand allows for streamlined and optimized assembly processes.

Comparative Analysis: Mini vs. Pneumatic vs. Air Impact Ratchet Wrenches

1. Size and Portability:

The Mini Air Ratchet Wrench excels in size and portability, making it ideal for tight spaces. The Pneumatic Air Ratchet Wrench offers a balance between size and power, while the Air Impact Ratchet Wrench prioritizes power over compactness.

2. Power and Torque:

The Pneumatic Air Ratchet Wrench and Air Impact Ratchet Wrench are designed for high power and torque, with the latter excelling in heavy-duty applications. The Mini Air Ratchet Wrench is more suitable for tasks that require precision in confined spaces.

3. Versatility:

The Mini Air Ratchet Wrench is versatile in navigating tight spaces, the Pneumatic Air Ratchet Wrench is versatile across industries, and the Air Impact Ratchet Wrench is versatile in handling heavy-duty tasks. Each type offers versatility in specific applications.

4. Operator Fatigue:

The Mini Air Ratchet Wrench minimizes operator fatigue due to its compact size, the Pneumatic Air Ratchet Wrench reduces fatigue through pneumatic power, and the Air Impact Ratchet W

rench minimizes manual effort with its impact mechanism.

Conclusion: Tailoring Efficiency to Every Task

In conclusion, the Mini Air Ratchet Wrench, Pneumatic Air Ratchet Wrench, and Air Impact Ratchet Wrench stand as importanttools in the world of mechanical work. From the precision of the mini variant to the power of pneumatic operation and the impact mechanism of the air impact wrench, each type addresses specific needs in various industries.

Professionals and enthusiasts alike can benefit from understanding the important features and applications of these air ratchet wrenches. Whether navigating tight spaces in automotive repairs, handling diverse tasks in construction, or tackling heavy-duty applications in industrial settings, these tools offer a spectrum of capabilities that contribute to efficient and precise mechanical work. As technology continues to advance, these air ratchet wrenches remain at the forefront of innovation, providing the necessary tools to tailor efficiency to every task in the dynamic field of mechanical engineering and maintenance.