The Unmatched Versatility and Precision of Air Sanders

Oct 20, 2023

Introduction:

In the fields of woodworking, metalworking, and automotive refinishing, achieving a flawless finish demands precision, expertise, and the right tools. Among these tools, the air sander has emerged as an invaluable asset. Harnessing the power of compressed air, this mechanical device offers unparalleled convenience and efficiency, making it an indispensable tool in various industries.

Development and History:

The history of air sanders can be traced back to the early 20th century when the aviation industry first started using compressed air technology for grinding aircraft components. As technology advanced, this innovative tool quickly found its way into other industries. The popularity of air sanders began to soar due to their exceptional control and superior surface finishing capabilities. Since then, air sanders have become the go-to tool for precision work, repairs, and shaping.

Functionality and Versatility:

Air sanders are available in various types, including orbital sanders, dual-action sanders, and belt sanders, each designed for specific applications. Orbital sanders are ideal for smoothing and shaping surfaces, while dual-action sanders offer the added benefit of simultaneously rotating and oscillating, providing a swirl-free finish. Belt sanders, on the other hand, are specifically designed for quick material removal. The versatility of air sanders allows them to be used on a wide range of materials, such as wood, metal, fiberglass, and plastic, making them suitable for multiple applications.

Precision and Efficiency:

One of the most significant advantages of air sanders is their ability to deliver precise and consistent results. The compressed air power ensures a constant rotational speed, allowing for meticulous control over surface removal and leveling. The adjustable speed settings enable users to customize the sanding process based on the material and desired finish. This level of precision not only saves time but also eliminates the risk of over-sanding or damaging delicate surfaces.

Ergonomics and Operator Comfort:

Air sanders are designed with user comfort in mind. The lightweight and ergonomic design reduces operator fatigue during extended use. Additionally, many air sanders feature features such as vibration reduction technology and ergonomic handles to further enhance comfort and reduce the risk of repetitive strain injuries.

Maintenance and Longevity:

With proper care and maintenance, air sanders can provide years of reliable service. Regular cleaning and lubrication of the air sander's components, such as the bearings and air motor, are essential for optimal performance. Additionally, replacing worn-out sanding pads and abrasive discs will ensure consistent results and extend the lifespan of the tool.

Functionality and Features:

Air sanders are renowned for their exceptional functionality and a wide range of features that make them a go-to tool for professionals across various industries. These tools are designed to deliver precise sanding, polishing, and smoothing operations, offering the ability to seamlessly remove imperfections, refine surfaces, and create a professional-quality finish.

One key feature of air sanders is their variable speed control. This allows the user to adjust the sanding speed according to the task at hand, providing greater control and precision. Whether you need to remove layers of paint or gently sand delicate surfaces, the adjustable speed feature ensures optimal results without compromising the material.

Additionally, air sanders come with various sanding mechanisms, such as orbital sanding, random orbital sanding, and dual-action sanding. These mechanisms provide different patterns of motion, allowing for versatile applications. Whether you need to sand large areas quickly or tackle intricate contours with finesse, air sanders can accommodate a range of sanding needs.

Conclusion:

Air sanders have revolutionized the world of surface finishing, offering unmatched precision, versatility, and efficiency. Whether in woodworking, metalworking, or automotive refinishing, these powerful tools are essential for achieving professional-level finishes while minimizing effort and time. As technology continues to advance, we can expect even more innovative features and improvements in air sanders, further enhancing their capabilities and solidifying their position as irreplaceable tools in various industries.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

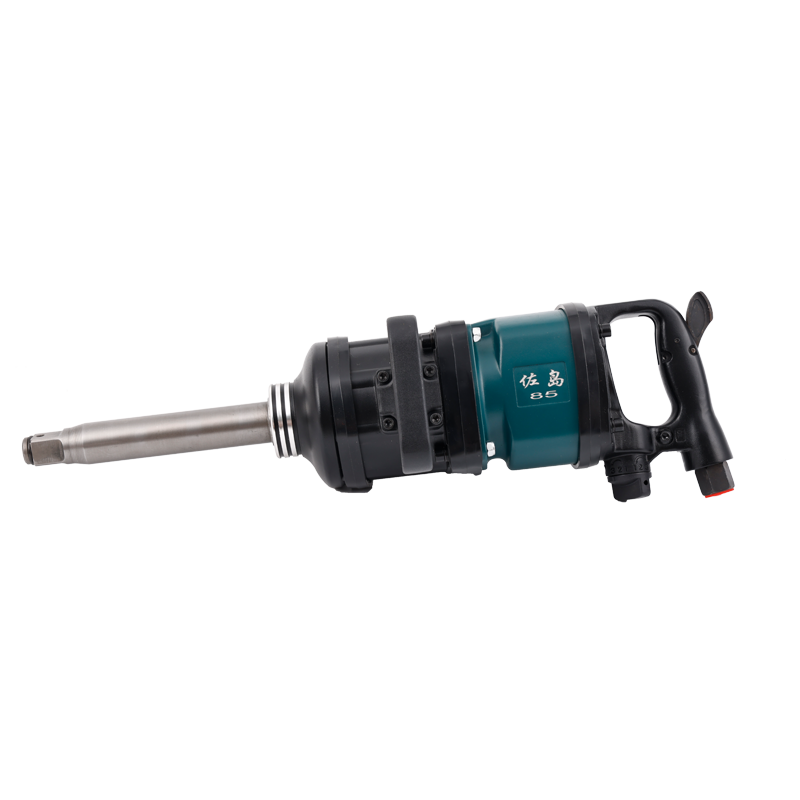

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

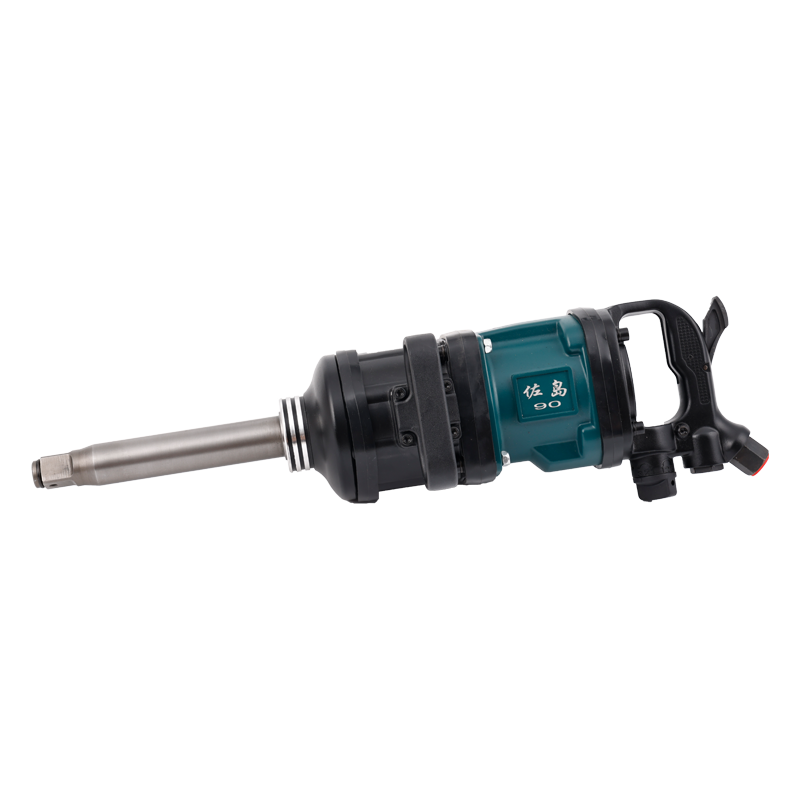

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский