Precautions for using pneumatic wrench

Dec 23, 2022

1. Pay attention to the position of the reversing switch before operation, so as to know the direction of rotation when operating the intake valve.

2. Ensure that the compressed air entering the wrench air motor is clean and dry air with a maximum pressure of 6.0bar, otherwise it may lead to dangerous situations such as transmission system failure, overspeed, rupture, and output torque error.

3. Make sure that all hoses and other connecting devices are of correct size and installed securely; do not use damaged, worn or aged air hoses and other connecting devices.

4. Operate the pneumatic wrench

When operating the pneumatic wrench, the body should be kept balanced and stable, and the operation should not be too large. In the process of opening and operating the pneumatic wrench, pay attention to preventing sudden changes in torque and force during exercise.

5. Some pneumatic wrenches are torque tools with a reaction arm. When using it, it is necessary to find a support point with sufficient strength for the reaction arm, and it should be far away from the working range of the reaction arm.

6. If you feel excessive noise and vibration during the use of the pneumatic wrench, stop the operation and check the pneumatic wrench to ensure that there is no problem with the wrench before working.

7. When using a pneumatic wrench, it is strictly forbidden to touch the rotating parts, and it is also forbidden to do actions that may touch the rotating parts.

8. The intake pipe should be disconnected before replacing the attachment of the wrench head.

9. Try to avoid tools

High-speed idling and air strikes, otherwise the tool will wear out too quickly and cause performance degradation.

10. Do not throw, drop or strongly impact the pneumatic wrench, otherwise it will cause damage, fall off or malfunction of the tool parts.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

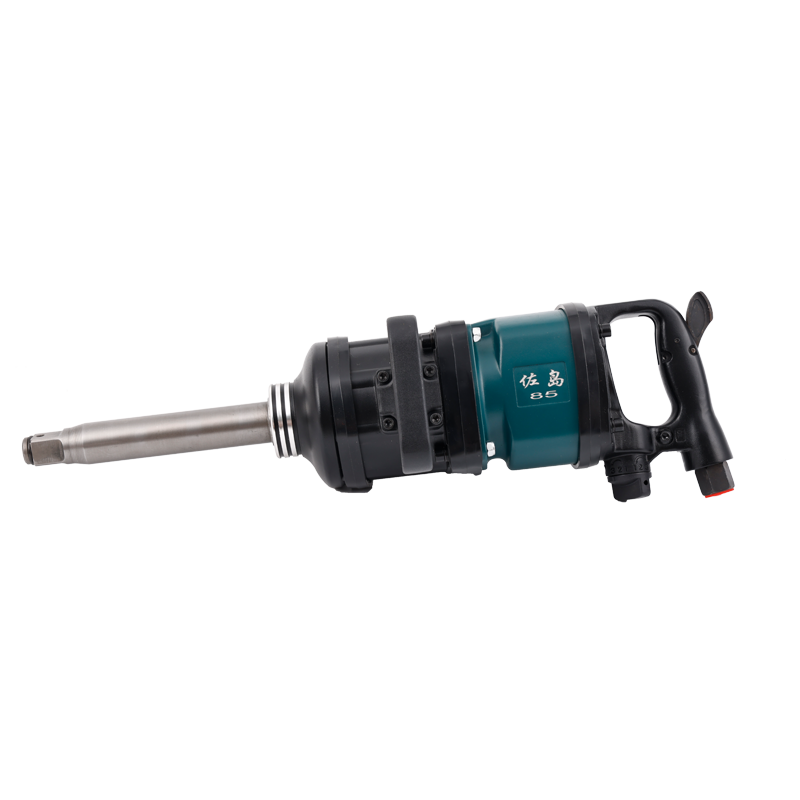

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

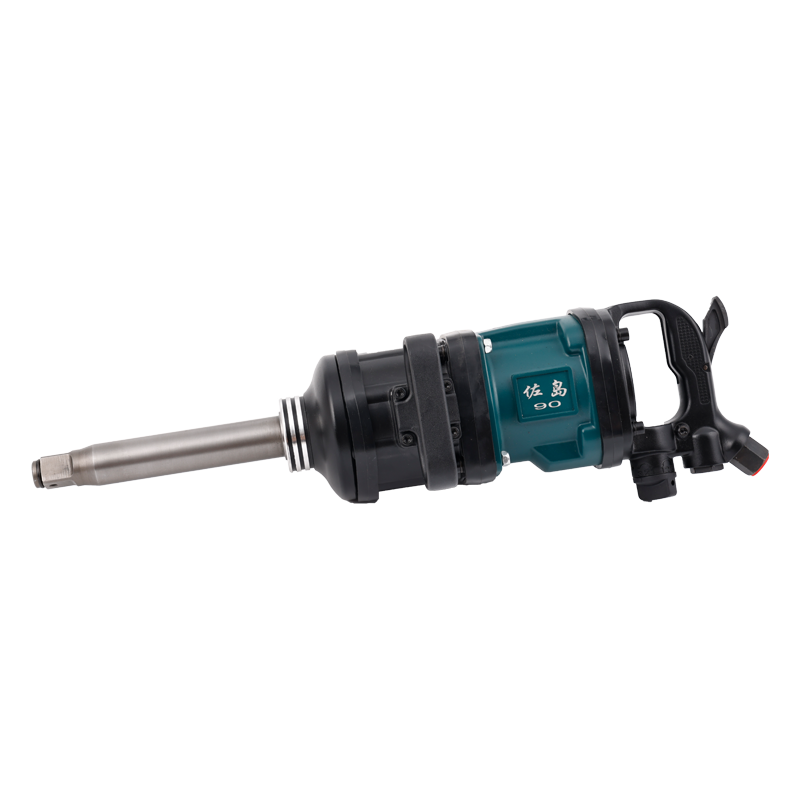

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский