Hydraulic wrench is suitable for many fields

May 25, 2022

The hydraulic torque wrench is composed of a working head, a hydraulic pump and a high-pressure oil pipe. Through the high-pressure oil pipe, the hydraulic pump transmits the power to the working head, which drives the working head to tighten or loosen the rotating nut. Hydraulic pumps can be driven by electricity or compressed air.

The working head of the hydraulic wrench is mainly composed of three parts, the frame (also called the shell), the oil cylinder and the transmission parts. The output force of the oil cylinder, the piston rod of the oil cylinder and the transmission part form a motion pair, the distance from the center of the oil cylinder to the center of the transmission part is the hydraulic wrench amplifying force arm, and the output of the oil cylinder multiplied by the force arm is the theoretical output torque of the hydraulic wrench. The actual output torque is less than the theoretical output torque.

Hydraulic torque wrench (hydraulic torque wrench, referred to as hydraulic wrench) is a professional bolt tightening tool for bolt installation and disassembly, which is powered by hydraulic pressure and provides high torque output. It is often used to tighten and loosen bolts larger than one inch. Thyssen Hydraulics tells you that the maximum output torque of hydraulic torque wrench can reach 110000Nm, which not only improves work efficiency and reduces labor intensity, but also greatly improves installation quality and is also conducive to on-site safety management.

Hydraulic wrenches are widely used. In shipbuilding, petrochemical, construction, electric power, mining, metallurgy and other industries such as construction, overhaul, and emergency repair, hydraulic wrenches are a very important tool for the installation and disassembly of large-sized bolts. Irreplaceable with other tools. Not only is it easy and light to air impact wrench factory use, but the torque provided is huge and accurate. The torque repeatability is about 3%. According to the statistics of the factory, about 50% of equipment failures are caused by bolt problems. At the same time, the number of major equipment accidents caused by bolt problems is also very alarming. Therefore, in the process of equipment installation, maintenance and gun repair, The torque requirements for bolt tightening and disassembly are relatively strict in most cases, and it is difficult to achieve the requirements by manual methods. Hydraulic wrenches are the ideal choice for bolts with large torques.

Because hydraulic wrenches are often used in small spaces and inconvenient locations during construction, the volume and weight of the wrench are the most important indicators. In order to reduce the size of components, the use of high-strength alloy materials and heat treatment are common methods.

The hydraulic wrench is generally composed of the hydraulic torque wrench body, the hydraulic torque wrench special station and the high-strength heavy-duty sleeve of the double high-pressure hose. The hydraulic wrench special pump has two driving modes, one is electric drive mode, the other is pneumatic Drive mode, after starting the hydraulic wrench hydraulic pump, the hydraulic torque wrench contains oil pipe medium, the pressure generated by foreign objects can transmit hydraulic oil through the medium, and push the oil rod of the hydraulic torque wrench to rotate the drive shaft to complete the pre-tightening and loosening of the bolts. Work.

Many people will tighten and remove the bolts, because hydraulic wrenches can help the staff to solve this heavy work, so it is often used to deal with the bolts, which can not only improve work efficiency, but also help reduce people's labor, but also Greatly improve the quality of installation. Hydraulic wrenches are mainly used in heavy metal and heavy machinery and other industries. They provide a large amount of torque output and use hydraulic pressure as power. They are used to install and remove professional bolt tools and tighten and loosen extremely large bolts. The hydraulic wrench is mainly composed of three parts, namely the frame, the oil cylinder and the rotating parts.

Today's China has a very large demand for hydraulic wrenches. It is needed in the construction industry, petrochemical industry, metallurgical industry, mining industry, electric power industry and ship engineering. It has become a popular tool in installation and disassembly. irreplaceable tool. The torque provided by the hydraulic wrench is huge and the data is very accurate, and the use of the hydraulic wrench is convenient and lightweight. According to the test, the repeatability of the hydraulic wrench is less than 5%. According to relevant statistical analysis, about 50% of the equipment is faulty due to bolt problems. Therefore, the torque requirements related to the tightening and disassembly of the bolts are very strict in the installation process and emergency repair process of the equipment.

All in all, hydraulic wrenches play an important role in many fields, and no one can replace them.

The working head of the hydraulic wrench is mainly composed of three parts, the frame (also called the shell), the oil cylinder and the transmission parts. The output force of the oil cylinder, the piston rod of the oil cylinder and the transmission part form a motion pair, the distance from the center of the oil cylinder to the center of the transmission part is the hydraulic wrench amplifying force arm, and the output of the oil cylinder multiplied by the force arm is the theoretical output torque of the hydraulic wrench. The actual output torque is less than the theoretical output torque.

Hydraulic torque wrench (hydraulic torque wrench, referred to as hydraulic wrench) is a professional bolt tightening tool for bolt installation and disassembly, which is powered by hydraulic pressure and provides high torque output. It is often used to tighten and loosen bolts larger than one inch. Thyssen Hydraulics tells you that the maximum output torque of hydraulic torque wrench can reach 110000Nm, which not only improves work efficiency and reduces labor intensity, but also greatly improves installation quality and is also conducive to on-site safety management.

Hydraulic wrenches are widely used. In shipbuilding, petrochemical, construction, electric power, mining, metallurgy and other industries such as construction, overhaul, and emergency repair, hydraulic wrenches are a very important tool for the installation and disassembly of large-sized bolts. Irreplaceable with other tools. Not only is it easy and light to air impact wrench factory use, but the torque provided is huge and accurate. The torque repeatability is about 3%. According to the statistics of the factory, about 50% of equipment failures are caused by bolt problems. At the same time, the number of major equipment accidents caused by bolt problems is also very alarming. Therefore, in the process of equipment installation, maintenance and gun repair, The torque requirements for bolt tightening and disassembly are relatively strict in most cases, and it is difficult to achieve the requirements by manual methods. Hydraulic wrenches are the ideal choice for bolts with large torques.

Because hydraulic wrenches are often used in small spaces and inconvenient locations during construction, the volume and weight of the wrench are the most important indicators. In order to reduce the size of components, the use of high-strength alloy materials and heat treatment are common methods.

The hydraulic wrench is generally composed of the hydraulic torque wrench body, the hydraulic torque wrench special station and the high-strength heavy-duty sleeve of the double high-pressure hose. The hydraulic wrench special pump has two driving modes, one is electric drive mode, the other is pneumatic Drive mode, after starting the hydraulic wrench hydraulic pump, the hydraulic torque wrench contains oil pipe medium, the pressure generated by foreign objects can transmit hydraulic oil through the medium, and push the oil rod of the hydraulic torque wrench to rotate the drive shaft to complete the pre-tightening and loosening of the bolts. Work.

Many people will tighten and remove the bolts, because hydraulic wrenches can help the staff to solve this heavy work, so it is often used to deal with the bolts, which can not only improve work efficiency, but also help reduce people's labor, but also Greatly improve the quality of installation. Hydraulic wrenches are mainly used in heavy metal and heavy machinery and other industries. They provide a large amount of torque output and use hydraulic pressure as power. They are used to install and remove professional bolt tools and tighten and loosen extremely large bolts. The hydraulic wrench is mainly composed of three parts, namely the frame, the oil cylinder and the rotating parts.

Today's China has a very large demand for hydraulic wrenches. It is needed in the construction industry, petrochemical industry, metallurgical industry, mining industry, electric power industry and ship engineering. It has become a popular tool in installation and disassembly. irreplaceable tool. The torque provided by the hydraulic wrench is huge and the data is very accurate, and the use of the hydraulic wrench is convenient and lightweight. According to the test, the repeatability of the hydraulic wrench is less than 5%. According to relevant statistical analysis, about 50% of the equipment is faulty due to bolt problems. Therefore, the torque requirements related to the tightening and disassembly of the bolts are very strict in the installation process and emergency repair process of the equipment.

All in all, hydraulic wrenches play an important role in many fields, and no one can replace them.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

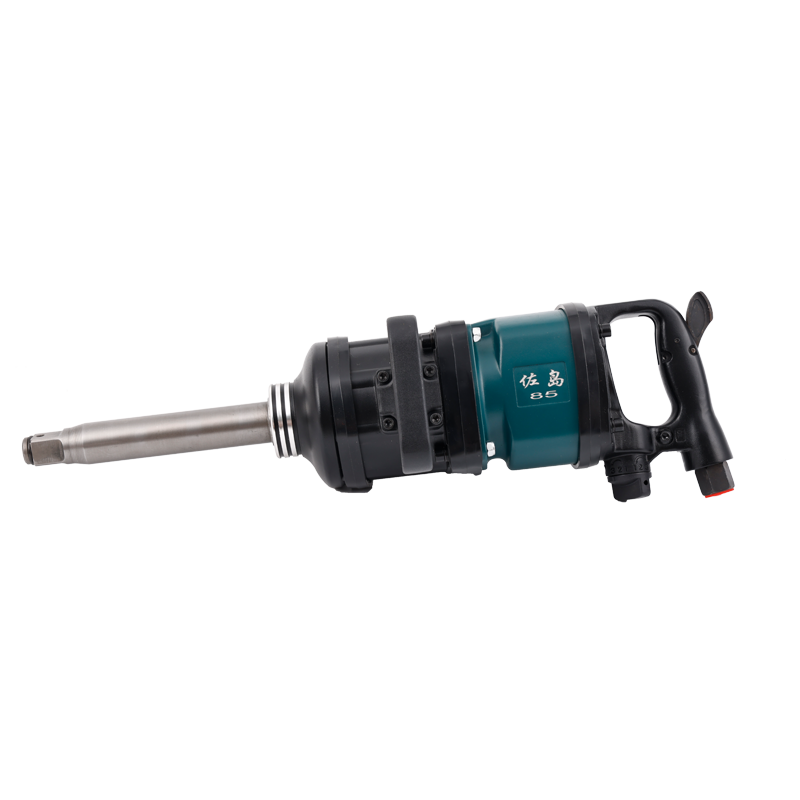

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

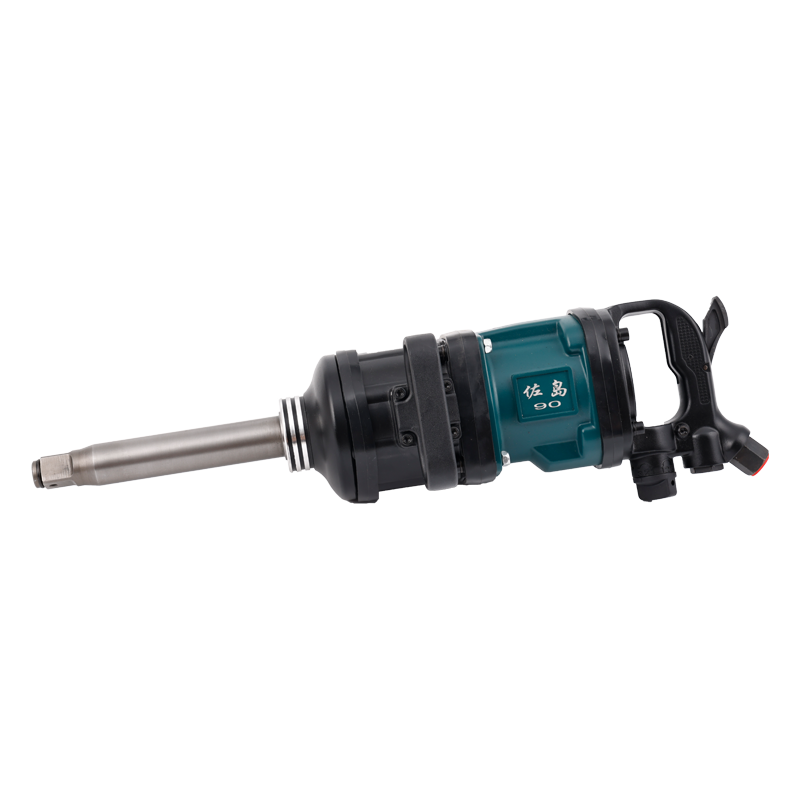

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский