How to Use an Air Tool

Nov 05, 2022

An air tool is a type of power tool that uses compressed air. This air is usually supplied by an air compressor. However, it can also be powered by carbon dioxide stored in small cylinders. This type of power tool is useful for many different jobs, including construction, repair, and maintenance. To use this type of tool, you'll need to know a few basic things.

First, make sure you have the correct air pressure. While an air tool can be very quiet when in use, excessive air pressure can damage surfaces or the hands of the operator. Excess air pressure can also lead to excessive torque, which can damage the tool. Likewise, an inadequate air pressure can cause it to shut off.

Another key benefit of air tools is their portability and lightweight design. This makes them ideal for long-term use. They can also be used in difficult to reach places and can be switched between applications quickly. A good air regulator is also an essential part of an air tool. The regulator can be adjusted to provide the exact amount of air pressure required for the application. A good air regulator will also maintain a consistent air pressure.

Another important factor to consider when purchasing an air tool is its CFM. Each tool requires different amounts of air. For example, a small right angle die grinder requires around 25 CFM, whereas a large impact wrench requires 60 CFM.

First, make sure you have the correct air pressure. While an air tool can be very quiet when in use, excessive air pressure can damage surfaces or the hands of the operator. Excess air pressure can also lead to excessive torque, which can damage the tool. Likewise, an inadequate air pressure can cause it to shut off.

Another key benefit of air tools is their portability and lightweight design. This makes them ideal for long-term use. They can also be used in difficult to reach places and can be switched between applications quickly. A good air regulator is also an essential part of an air tool. The regulator can be adjusted to provide the exact amount of air pressure required for the application. A good air regulator will also maintain a consistent air pressure.

Another important factor to consider when purchasing an air tool is its CFM. Each tool requires different amounts of air. For example, a small right angle die grinder requires around 25 CFM, whereas a large impact wrench requires 60 CFM.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

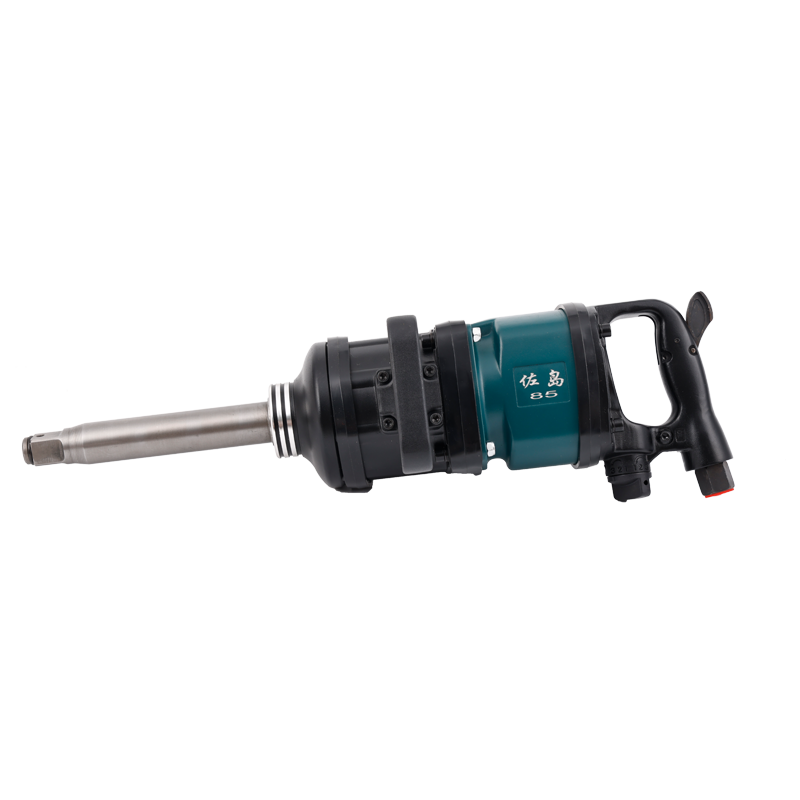

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

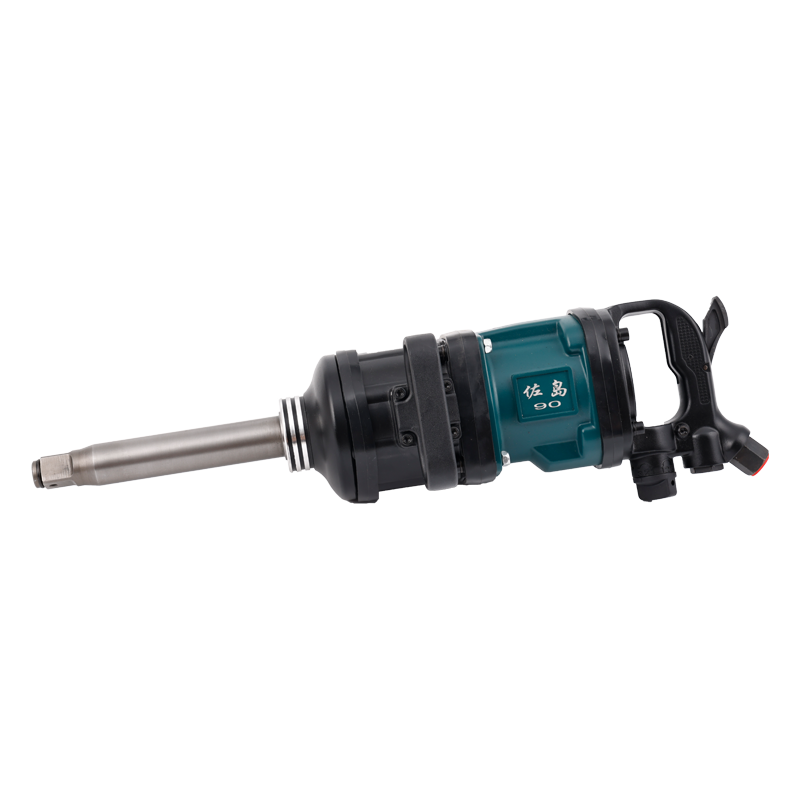

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский