How to use a pneumatic wrench

Apr 07, 2022

1. Air pressure adjustment

The pneumatic wrench adjusts the air pressure through the regulator on the oil-water separator. When the regulator is turned forward, the air pressure increases; when the regulator is reversed, the air pressure decreases.

When adjusting the air pressure, make sure that the wrench is in an idling state (forward or reverse rotation).

Notice:

1. The water storage tank of the oil-water separator should be emptied regularly (the bottom of the water storage tank can be removed).

2. Before use, make sure that the capacity and pressure of the air compressor are sufficient. During the operation of the tool, do not touch the reaction with both hands.

2. Torque setting

Each WREN pneumatic torque wrench is equipped with an "air pressure-torque comparison table", which maps the output torque to the air pressure.

Set the torque value as follows:

There are "L" and "R" marks on the left and right ends of the handle, and the direction of the knob E is set as forward rotation "R"

According to the required torque, determine the required pressure by referring to the "air pressure-torque comparison table"

Long press the slider G, then press the trigger F, the wrench is running at this time, while keeping the wrench running, adjust the pressure regulator until the pressure gauge shows the required pressure value.

Notice:

1. When adjusting the air pressure, the wrench must be in an idling state.

2. Exceeding the maximum air pressure will overload the wrench and may cause serious damage.

3. When the bolt needs to be loosened, the direction of the knob of the wrench should be set in the reverse (ie "L") position, and then the air pressure should be set to the maximum value.

3. Operation steps description

The pneumatic torque wrench operates as follows:

1. Install the reaction arm on the wrench and fix it with a retaining ring.

2. Install the socket on the square drive shaft of the wrench and fix it with ZUODAO PNEUMATIC IMPACT WRENCH locating pins and O-rings.

3. Check whether the direction of the knob setting is correct.

4. Turn the handle to an easy-to-operate direction.

5. Install the wrench on the bolt and bring the reaction arm close to the appropriate reaction fulcrum.

6. Long press the slider, and then press the trigger. At this time, the wrench is running, and the reaction arm is close to the reaction fulcrum.

7. Keep the wrench fully pressed until the wrench stops turning. If the wrench is loosened before the wrench stops turning, the wrench will not apply the full set torque to the bolt.

8. After the operation is completed, release the trigger and slider, and take off the wrench.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

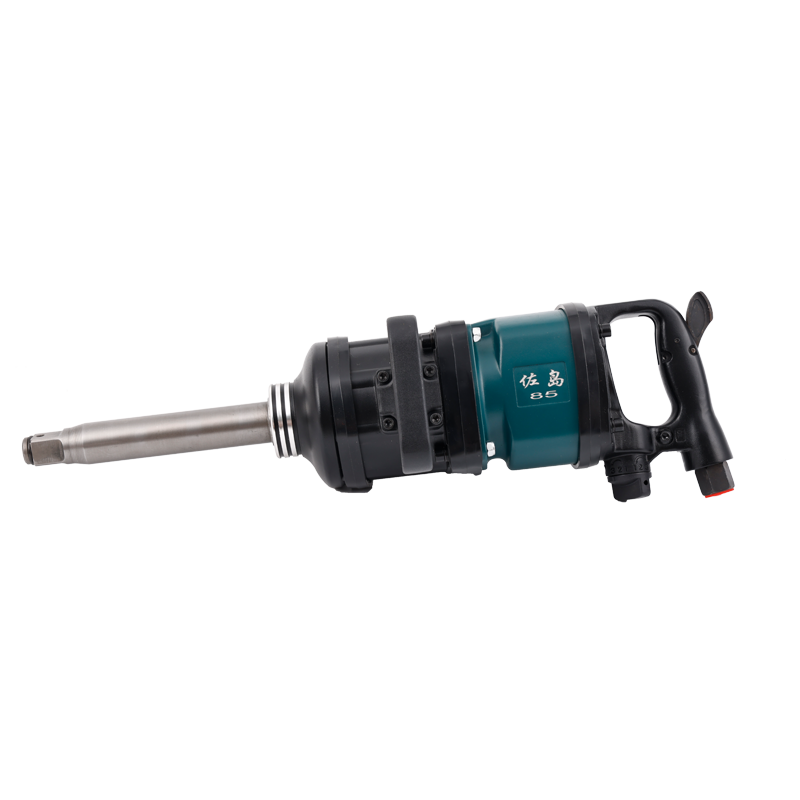

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

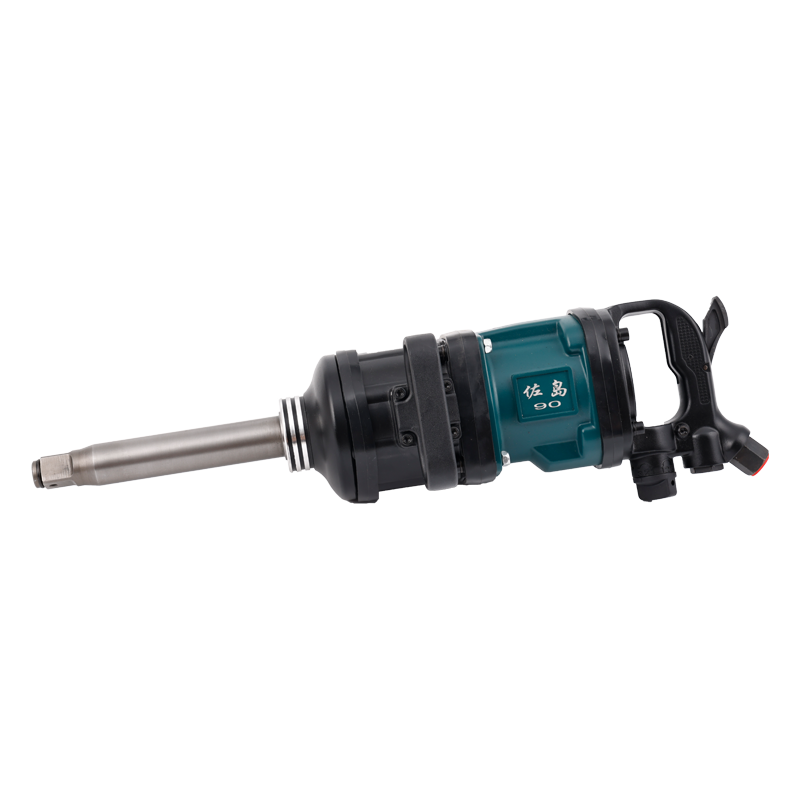

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский