How often does a hydraulic wrench need to be changed hydraulic oil?

Jul 26, 2022

Electric torque wrenches have been used in all walks of life, and many people are familiar with them. However, some details are still very important. In the process of operation, we have more precautions. Precautions for operation of electric torque wrench

1. The diameter of the bolt has a certain influence on the control accuracy. The same type of bolt connection should be used to calibrate the torque value during construction, and it should be checked and calibrated after a period of use.

2. The machine should be idling for 3-5 minutes before work. If it is found that the motor has large sparks, abnormal sound and unstable torque during operation, it should be stopped immediately for inspection, and do not work with illness.

3. Regular cleaning and replacement of grease, generally after 5000 times of work, should be cleaned and refueled once to prolong the service life. 4. The power switch on the host, the carbon brush, and the fuse on the controller are all wearing parts, which are easy to cause failure, and should be checked frequently and replaced in time.

5. If the screw on the tool is found to be loose during use, it should be tightened in time.

6. Do not lift the cable when carrying the tool, and pay attention to handle it with care to prevent vibration and falling. It should be placed in a ventilated and dry place when not in use. If it is found to Custom 1 impact wrench be damp, it should be dried in time. It should not be in contact with or stored together with harmful substances such as acids and alkalis.

How often should the hydraulic wrench change the hydraulic oil?

In general, we recommend that the hydraulic wrench pump should be replaced with new hydraulic oil for the first 100 hours of use, and then every 500 hours of use. However, in actual use, there is basically no way to determine the specific length of time used, so it can only be judged by checking the color status of the hydraulic oil. Observe that the color of the hydraulic oil turns black. It is more likely that the distribution valve spool is running back and forth, and the pollution caused by the wear and tear caused by the back and forth operation of the hydraulic cylinder. This phenomenon will not occur in a short time. Once it occurs, it means that the hydraulic oil needs to be replaced. And do maintenance.

Three Easier Ways to Confirm If You Need an Oil Change?

1. Regular oil change method

According to the environmental conditions and working conditions of the site where the equipment is located, and the oil change cycle of the oil used, it will be replaced when it is due. This method is very suitable for enterprises with more hydraulic equipment.

2. Visual oil change method

When should hydraulic oil be changed? It is based on the experience of the maintenance personnel, and according to some visual changes in the normal state of the oil, such as the oil turning black, smelly, milky white, etc., to decide whether to change the oil.

3. Sampling assay

Regularly sample and test the oil in the hydraulic press to determine the necessary items (such as viscosity, acid value, moisture, particle size and content, and corrosion, etc.) and indicators, according to the actual measured value of oil quality and the specified oil deterioration standard. Compare and determine whether the oil should be changed.

What factors affect the service life of hydraulic wrenches?

The frequency of daily use is high and for a long time. In addition, it is also very important to maintain the hydraulic wrench well. If the hydraulic oil is not changed frequently and wiped frequently, the surface will be covered with dust or oil, and the wrench should be kept as clean as possible. In addition, for the working environment used, try to keep the surrounding environment clean and tidy to prevent fine oil fume, dirt and dust from entering the hydraulic wrench, so as to affect its performance and service life.

1. The diameter of the bolt has a certain influence on the control accuracy. The same type of bolt connection should be used to calibrate the torque value during construction, and it should be checked and calibrated after a period of use.

2. The machine should be idling for 3-5 minutes before work. If it is found that the motor has large sparks, abnormal sound and unstable torque during operation, it should be stopped immediately for inspection, and do not work with illness.

3. Regular cleaning and replacement of grease, generally after 5000 times of work, should be cleaned and refueled once to prolong the service life. 4. The power switch on the host, the carbon brush, and the fuse on the controller are all wearing parts, which are easy to cause failure, and should be checked frequently and replaced in time.

5. If the screw on the tool is found to be loose during use, it should be tightened in time.

6. Do not lift the cable when carrying the tool, and pay attention to handle it with care to prevent vibration and falling. It should be placed in a ventilated and dry place when not in use. If it is found to Custom 1 impact wrench be damp, it should be dried in time. It should not be in contact with or stored together with harmful substances such as acids and alkalis.

How often should the hydraulic wrench change the hydraulic oil?

In general, we recommend that the hydraulic wrench pump should be replaced with new hydraulic oil for the first 100 hours of use, and then every 500 hours of use. However, in actual use, there is basically no way to determine the specific length of time used, so it can only be judged by checking the color status of the hydraulic oil. Observe that the color of the hydraulic oil turns black. It is more likely that the distribution valve spool is running back and forth, and the pollution caused by the wear and tear caused by the back and forth operation of the hydraulic cylinder. This phenomenon will not occur in a short time. Once it occurs, it means that the hydraulic oil needs to be replaced. And do maintenance.

Three Easier Ways to Confirm If You Need an Oil Change?

1. Regular oil change method

According to the environmental conditions and working conditions of the site where the equipment is located, and the oil change cycle of the oil used, it will be replaced when it is due. This method is very suitable for enterprises with more hydraulic equipment.

2. Visual oil change method

When should hydraulic oil be changed? It is based on the experience of the maintenance personnel, and according to some visual changes in the normal state of the oil, such as the oil turning black, smelly, milky white, etc., to decide whether to change the oil.

3. Sampling assay

Regularly sample and test the oil in the hydraulic press to determine the necessary items (such as viscosity, acid value, moisture, particle size and content, and corrosion, etc.) and indicators, according to the actual measured value of oil quality and the specified oil deterioration standard. Compare and determine whether the oil should be changed.

What factors affect the service life of hydraulic wrenches?

The frequency of daily use is high and for a long time. In addition, it is also very important to maintain the hydraulic wrench well. If the hydraulic oil is not changed frequently and wiped frequently, the surface will be covered with dust or oil, and the wrench should be kept as clean as possible. In addition, for the working environment used, try to keep the surrounding environment clean and tidy to prevent fine oil fume, dirt and dust from entering the hydraulic wrench, so as to affect its performance and service life.

hot Products

-

ZD70 AIR IMPACT WRENCH 1-INCH ZUODAO PIN CLUTCH STRAIGHT/LONG ANVIL SUPER-DUTY

-

ZD76 1" LONG NOSE TWIN HAMMER HEAVY DUTY ZUODAO AIR PNEUMATIC IMPACT WRENCH 5000N.M

-

ZD78 CAR PNEUMATIC 1" SPANNER TIRE REPAIR ZUODAO TOOL

-

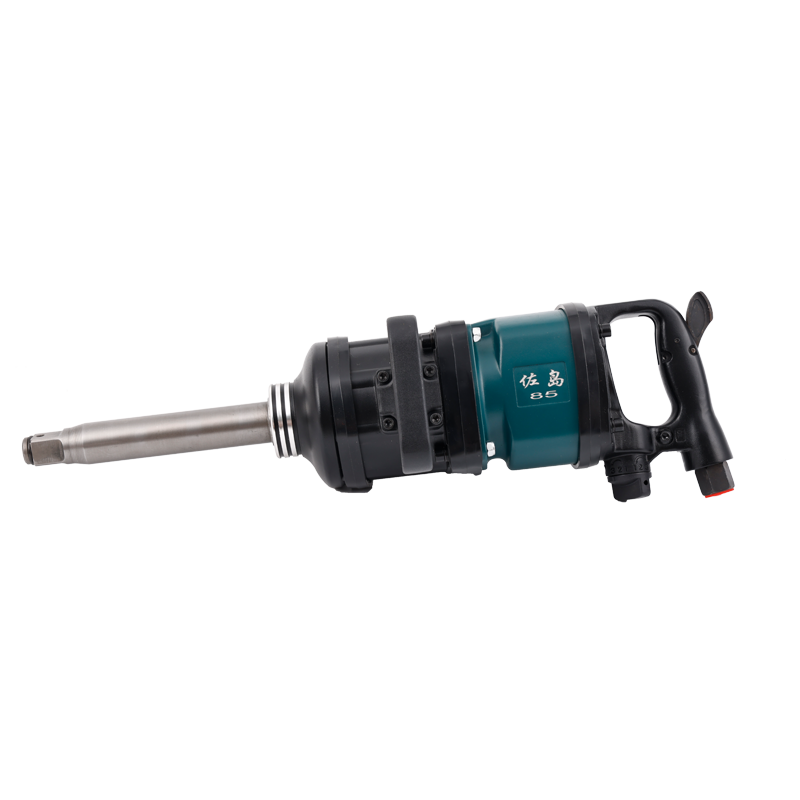

ZD85 POWERFUL 1" SUPER DUTY STRAIGHT ZUODAO AIR TORQUE WRENCH

-

ZD88 IMPACT WRENCH 1"SQ DRIVE HEAVY-DUTY AIR TOOLS ZUODAO AIR WRENCH

-

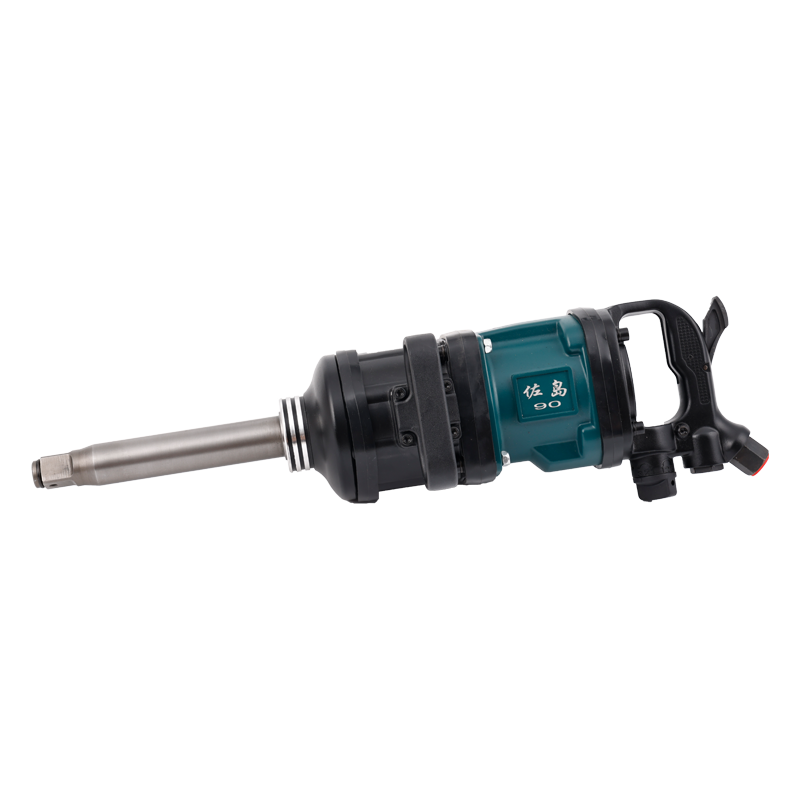

ZD90 AIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.MAIR 1" IMPACT WRENCH GUN ZUODAO MAX TORQUE 5800N.M

-

ZD95 1" INDUSTRIAL ZUODAO AIR IMPACT WRENCH

-

ZD100 HEAVY DUTY 1” 3-SPEED PNEUMATIC ZUODAO IMPACT WRENCH TOOL

-

ZD105 PNEUMATIC 1" IMPACT WRENCH ZUODAO PROFESSIONAL

-

ZD108 ZUODAO 1" ADJUSTABLE POWER IMPACT WRENCH

English

English русский

русский